- Mechanical properties at cryogenic temperatures and up to 1000°C

- Thermal properties at cryogenic temperatures and up to 1600°C

- X-ray diffraction at elevated temperatures

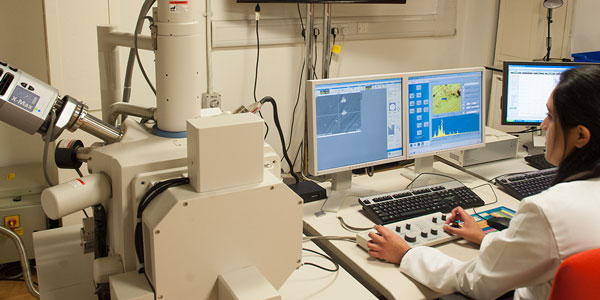

- Non-destructive topographical and morphological investigations and elemental analyses of small parts (i.e. no need for materialographic preparation)

Advanced Materials Research LaboratoryRange of analyses

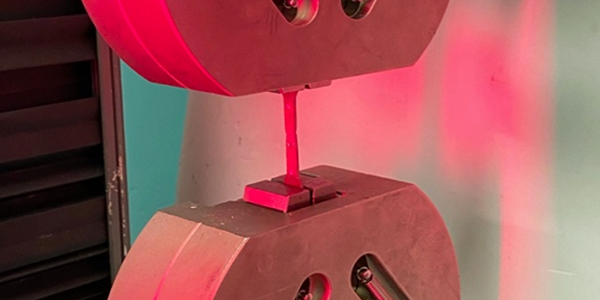

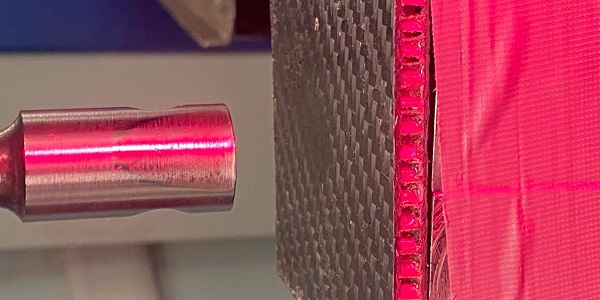

Mechanical testing

- tension/compression

- axial fatigue

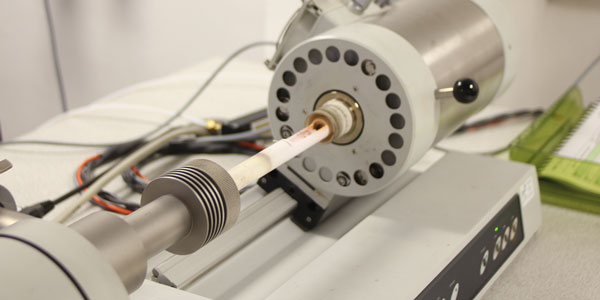

- rotary bending fatigue

- 3- or 4- point bending

- creep

- impact V-Charpy

- Vickers macro- and micro-hardness

Thermal analysis

- thermal diffusivity and specific heat (≤1600°C and in inert gas/vacuum conditions)

- weight change and face transformations (≤1600°C)

- coefficient of thermal expansion (≤1600°C)

- thermal conductivity - indirect measurement (≤1600°C and in inert gas/vacuum conditions)

- thermal conductivity - direct measurement (-20°C to 80°C)

Compositional analysis

- qualitative and semi-quantitative elemental analysis

- quantitative mapping

- phase and material identification (≤2000°C)

- compositional depth profiling (≤150μm)

- quantitative surface, interface and bulk analysis

Microstructural analysis

- morphological imaging

- topographical imaging

- crystallography (grain size and texture analysis)

- porosity and inclusions characterisation

Corrosion and tribology

- Accelerated corrosion testing under controlled salt spray conditions (e.g. ASTM B117, ISO 9227)

- Evaluation of corrosion resistance and coating durability of metallic materials

- Abrasive wear testing using sand–rubber wheel and wheel abrasion configurations

- Quantitative measurement of wear rate and material or coating durability

Bespoke testing

Our research

Read about our latest research projects