Centre for Precision ManufacturingOur research

Our areas of research

Precision-Forming and Micro-Manufacturing: led by Prof. Yi Qin

This concerns three areas of Materials Forming and Micro-Manufacturing:

- Forming processes development (cold, warming and hot forming). The group researches and develops the forming processes concerning: Micro-range precision manufacture of macro-sized components; Micro-feature manufacturing over the large areas; Manufacture of micro-sized components through micro-forming, hot-embossing and fast sintering; and Manufacture with micro/nano-structured materials with an innovative process called Micro-FAST;

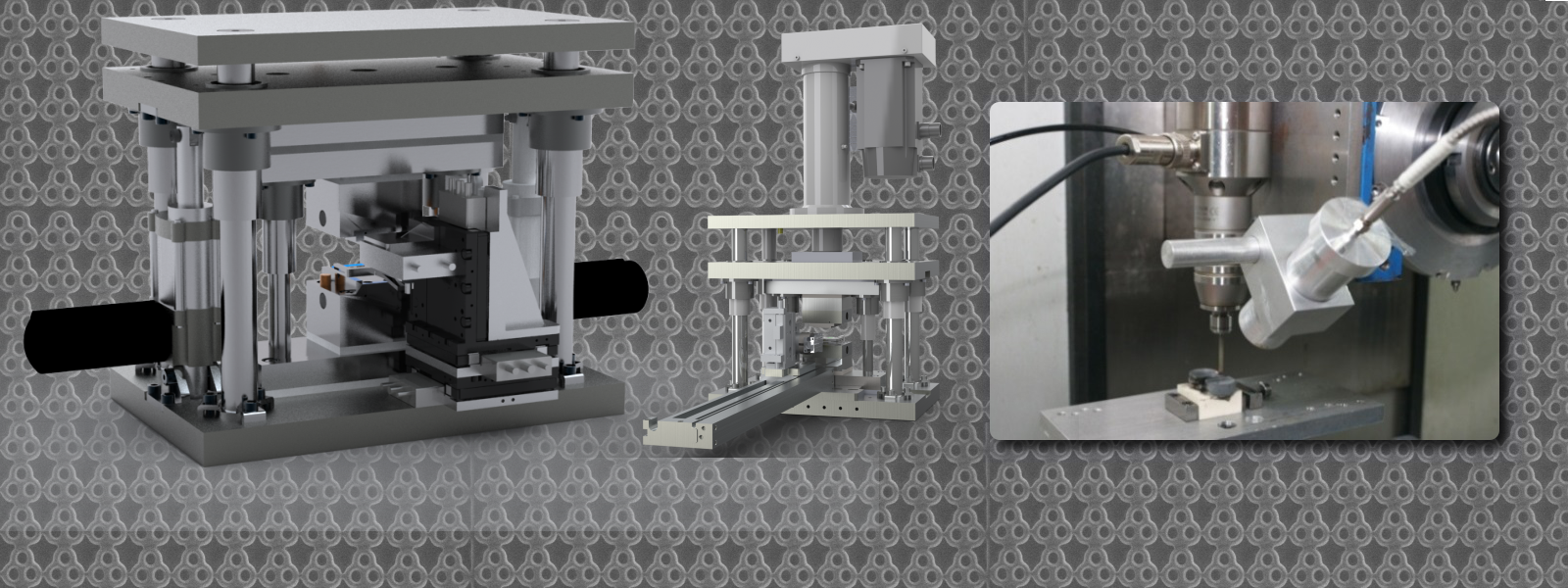

- Developing tool designs and tooling techniques, including multi-layered coatings, intelligent forming-tools, flexible, multi-points forming tools and electric-field-activated micro-forming and sintering tools; and

- Developing bench-top manufacturing machines and systems, including forming press designs, handling, inspection and automation designs and system constructions. The group has achieved an international leading status in micro-manufacturing research, and being recognised worldwide. The research in this theme will be complimentary to AFRC’s activities in precision-forging/forming and tooling development, and will bridge between AFRC, re-manufacturing, design group and other departments’ centres.

Precision Engineering: led by Prof. Xichun Luo

We develop processes for freeform ultra precision diamond turning, diamond grinding and diamond milling. Non-ferrous metal, crystal brittle materials such as CaF2, Si and SiC for aerospace, defence, high power electric and quantum computing applications are group's key interested work-materials.

Recently, the group has extended its expertise to hard turning of steel which serves the high demand of automotive industry. Optical quality (nanometre level) surface finish on the product can be achieved.

The group is also focused on the development of a hybrid micromachining approach i.e. combination of laser micromachining with mechanical micromachining for cost-effective manufacturing of micro-products such as microfluidics and micro-pins for biomedical and energy applications. Development of a hybrid micro machine tool and integration within a miniature flexible and reconfigurable manufacturing system is a key task of our current EPSRC project.

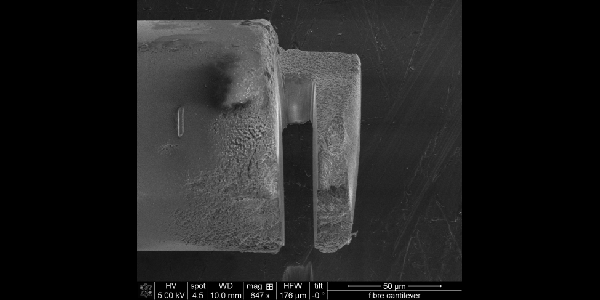

The group also works on the development of deterministic focused ion beam (FIB) machining approach for the fabrication of plasmonic nanostructures for bio-imaging, data storage and nano-lithograph applications. It is assisted by Monte Carlo (MC) simulation and level set method. The group is currently working toward a scale-up nanomanufacturing approach for commercialisation of the next generation of nanoproducts. The research in this theme will be complimentary to AFRC’s activities in tooling development and metrology, and will bridge between AFRC, re-manufacturing, design group and other departments’ centres.

Light Metals Advanced Technology: led by Dr. Andrzej Rosochowski

The main focus of the theme-group is a novel technology of producing ultrafine grained lightweight metals (aluminium, magnesium, titanium) through "Grain Refinement in Metals by Severe Plastic Deformation". The scope is to develop industrially viable processes, which can improve material structure and properties. The areas of application are in the aerospace, medical, automotive, micro-manufacturing, energy, defence and sport equipment industries.

The group specialises in finite element simulation of new severe plastic deformation processes in order to predict material flow and microstructure. The group also works on the modelling of damage in ductile metals: Constitutive modelling of metal damage due to void nucleation, growth and fracture is linked with prediction of plastic flow localisation, which limits formability of metal formed parts. It also addresses the environmental impact - the environmental aspects of using lightweight metals are addressed by promoting net shape metal forming and recycling metals in the solid state. The research in this theme will be complimentary to AFRC’s activities in materials and forming-processes, and will bridge between AFRC and AMRL.

Multiscale Modelling of Materials and Processes: led by Prof. Yi Qin, Prof. Xichun Luo and Dr. Andrzej Rosochowski

Current activities include:

- Modelling and analysis of materials, micro-devices/instruments, micro-forming processes and tools, including using First Principle Calculation (atomistic scale), Molecular Dynamics, CFD, elastic-plastic, electro-heat-structural analysis, submodelling and cohesive-zone modelling;

- (Molecular Dynamics, Finite Element and multi-scale simulation for a fundamental understanding of ultra precision machining mechanism and tool wear mechanism; and

- Modelling of multi-stage materials forming processes and material damages. Typical examples are multi-scale modelling of multi-layered engineering systems (EU FP7 M3-2S project) and multi-scale modelling of hybrid micro-machining processes (EPSRC Micro-3D project). The research in this theme is complimentary to AFRC’s activities in materials and forming-process modelling.