Enabling Technologies ConsortiumDevelopment of a Spatially Resolved Spectroscopy Probe for Application in Pharmaceutical Drying Processes

Project Overview

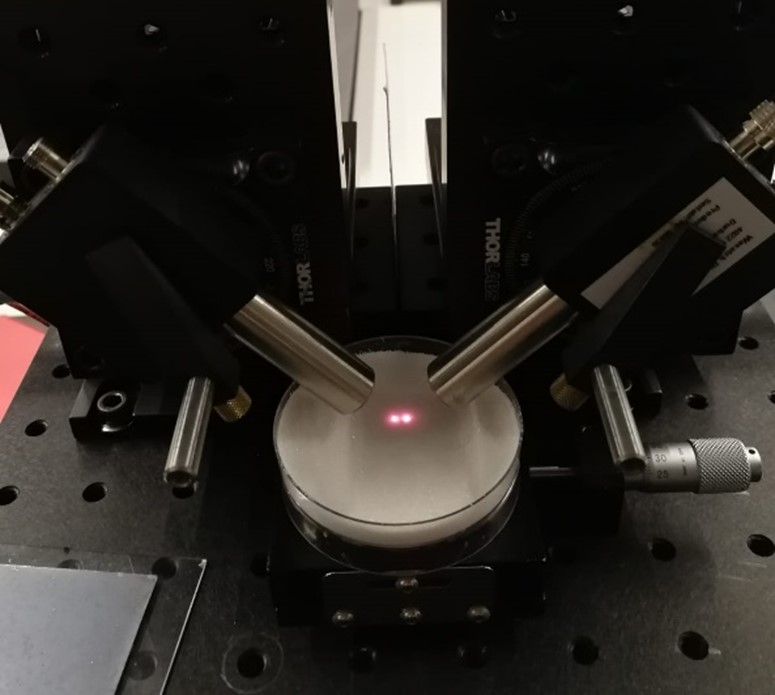

Pharmaceutical drying is a complex process. This is, in part, due to the variable drying rates within the nonhomogeneous wet powder. This leads to inaccurate measurements of the solvent content and, eventually, the drying endpoint, affecting critical quality attributes of the pharmaceutical product. Conventional optical spectroscopy-based process analytical technologies (PAT) can only probe chemical information near the surface and are not capable of fully capturing powder properties. Therefore, current PAT are limited in accuracy when applied in nonhomogeneous media, as properties obtained from a surface do not represent the bulk mixture. Spatially resolved spectroscopy offers the means to probe the subsurface of heterogeneous media by collecting signals from light travelling farther through the sample.

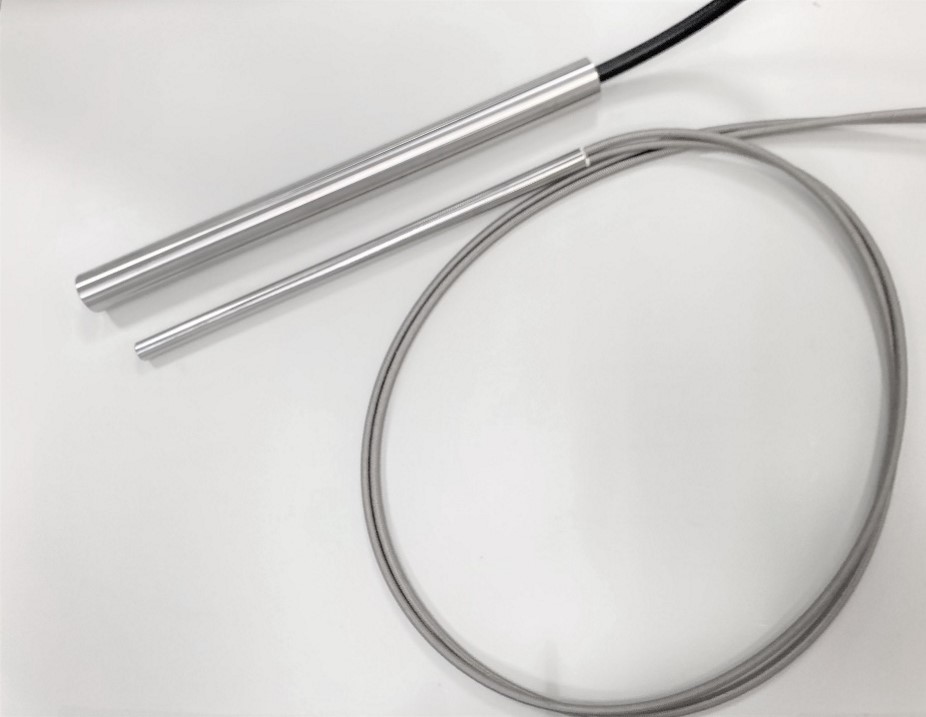

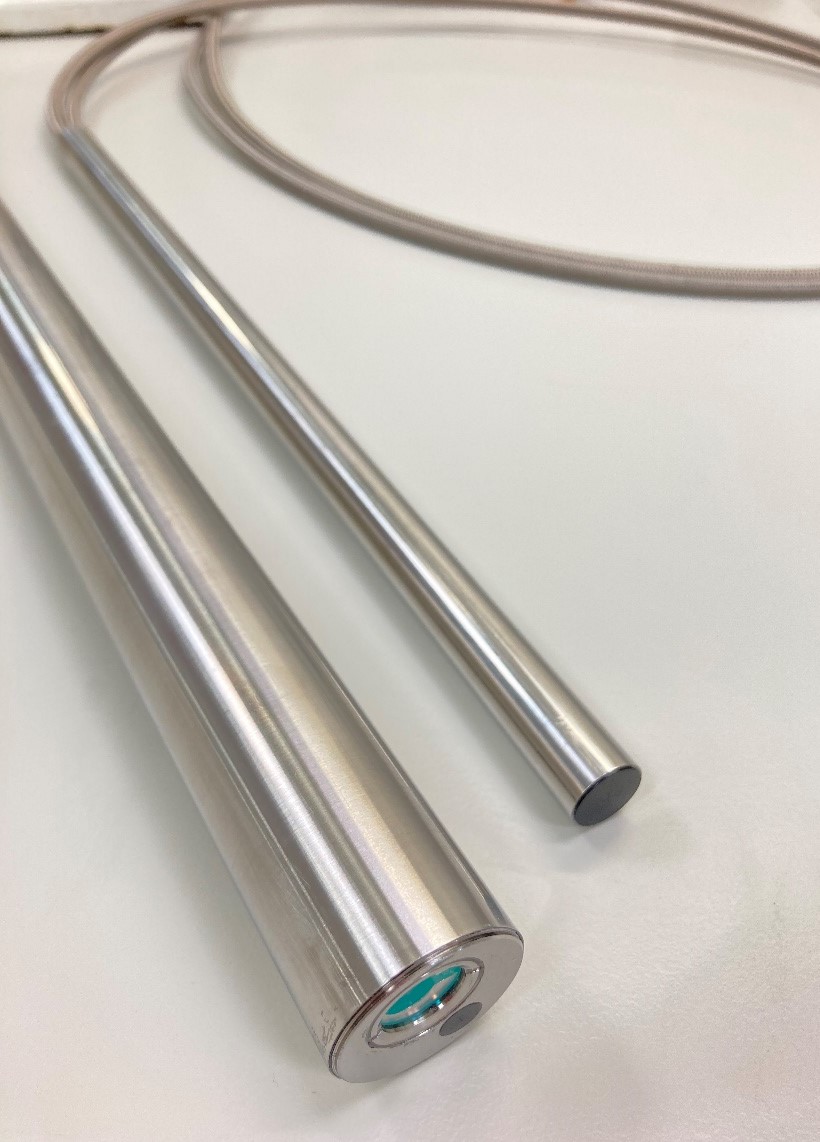

In this project, spatially resolved near-infrared and Raman spectroscopy probes for inline monitoring of the drying process is developed. Due to the nature of spatially resolved spectroscopy, it is a data-dense technique that provides a larger amount of data compared to conventional PAT. A systematic analysis is performed to evaluate and harness the benefits of spatially resolved spectra from the probe. The combination of unique in-line measurement and the analysis enables the obtaining insight into subsurface powder drying behaviour. This pave the way for industries to address the limitation of existing inline measurement techniques and replace the time-consuming offline analysis.

Why Strathclyde

Situated in Glasgow, the city of science and innovation, the University of Strathclyde is a producer of world-leading and internationally excellent research. More importantly, it is home to the expertise of Dr Yi-chieh (Claudia) Chen, Prof. Chris Price, whose research focuses on measurement science and process development, and Prof. Karen Faulds, with focus on bionanotechnology and analytical chemistry. Dr Chen’s research revolves around the development of innovative analytical instruments for process measurement and monitoring with a propensity towards exploring novel techniques, with particular expertise in spatially resolved optical spectroscopy. Prof. Price’s research spans to cover the filtration, washing, and drying of pharmaceutical manufacturing processes backed by years of industrial expertise in the pharmaceutical sector. Prof. Faulds’ research thrives on the creation of novel approaches for the exploitation of Raman spectroscopy for bioanalysis and extends to include spatially offset Raman spectroscopy. In addition to leveraging the expertise of the academic team, the University of Strathclyde’s internationally leading Centre for Continuous Manufacturing and Advanced Crystallisation (CMAC), where the project work is conducted, provides excellent state-of-the-art facilities for growing research ideas and demonstrating the potential impact in an industrially-relevant environment.

Researchers Experience

Through the collaboration with the Enabling Technologies Consortium, it was possible to benefit from the know-how of the Drying PAT Working Group on the operation and challenges faced in the development and implementation of the pharmaceutical drying process and the use and requirements of the PAT tools. This led to the swift identification of specific objectives that would address the overall aims of the project. This has also helped the team in producing an output that would, later on, be translatable within their large-scale industrial settings.

Business Impact

The current state of drying process development is driven by trial-and-error approaches which can only indirectly assess impact of process parameters on critical API properties. The lack of an approach to assess these changes during drying puts a great strain on scale-up development efforts within the pharmaceutical industry. Essentially, the industry cannot anticipate how API properties will change upon scale-up or when changing equipment trains.

The introduction of a PAT technology that directly measures changes to API properties (e.g., form, particle size, solvent content) during drying in real-time will lead to more robust data sets that will improve models for predicting drying kinetics, form transformations, and possibly attrition/agglomeration. Development scientists and engineers will be able to anticipate issues much earlier in the development process with smaller material quantities. The impact to the industry will greatly reduce the number of at-scale development experiments needed to validate a process.

This technology will serve as a catalyst to positively impact other critical unit operations in which process understanding may be driven by indirect methods. The ability to make measurements on material properties in dynamic processes in real-time will greatly improve and shorten development timelines and resources.