The development of a hydrogen (H₂) economy is a key part of the UK’s pathway to net zero by 2050. Achieving this will require the production and transport of large volumes of hydrogen, supported by a safe, reliable, and cost-effective pipeline transmission network.

However, hydrogen can negatively affect the mechanical behaviour of carbon steels. In particular, hydrogen embrittlement can reduce ductility and toughness, increasing the risk of cracking and long-term integrity issues. Understanding how hydrogen interacts with pipeline materials is therefore essential for both new infrastructure and the potential reuse of existing assets.

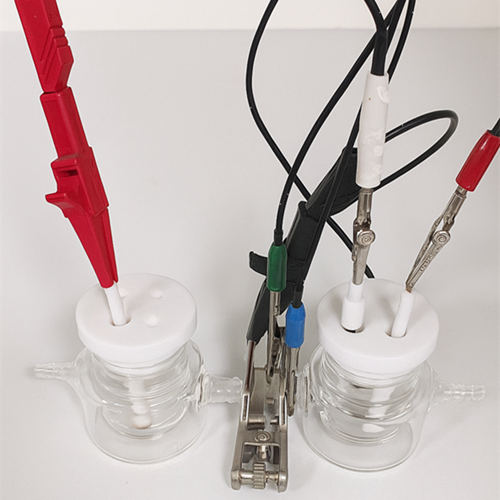

Our research evaluates the mechanical performance of pipeline steels exposed to hydrogen using established testing standards and sub-size specimen geometries. This includes measuring changes in fracture toughness and tensile behaviour under both in-situ and ex-situ hydrogen environments. These tests are supported by hydrogen permeation measurements, allowing us to directly relate hydrogen transport within the material to observed changes in mechanical performance.

Material response to hydrogen is strongly influenced by microstructure, which is shaped by composition, manufacturing processes, and service history. We investigate the role of grain structure, microstructural variation, inclusions, and surface conditions in governing hydrogen-related degradation. Permeation-based techniques are used to quantify hydrogen uptake and diffusion, providing insight into how microstructural features control hydrogen–material interactions.

This research contributes to:

• Improved understanding of how hydrogen is transported and interacts within pipeline steels.

• Develops links between hydrogen permeation behaviour and changes in mechanical performance.

• A materials-based approach to overcoming the technical challenges of hydrogen pipeline design and repurposing.