For our last blog of 2025, we thought we would do something a little different this year. We have created the 12 days of CI Christmas. Hope you enjoy!

On the ‘x’ Day of Christmas the Continuous Improvement Directorate made available to me…….

1 clear Strategy and the tools to implement it.

Clear understanding of team vision is critical to you and your team working towards the right goals. How do we self-problem solve if we don’t have a steer on the direction we are going?

2 Pillars of Lean – Continuous Improvement and Respect for people

CI isn’t just a one off event or something we do just before our annual review, it needs to be a conscious decision of how we challenge and perform every day. There will always be a best way to do something in that moment, and CI helps us tweak and adjust to this dynamically changing environment.

Respect for our people is how we do this. Those doing the job, aligned with a clear idea of the direction, are in the best place to suggest, implement, and maintain improvements. Ensure they have the permission and support to do so.

3 types of improvement idea

It’s great getting lots of ideas to improve but important for the smooth completion of them that we can categorise them correctly.

- Just Do It – This idea is simple, might take an hour or so, only needs one person to implement it, the decision is 100% the team’s to make.

- Considered Action – This idea has some complexity, might take a day or so, maybe needs more than one person to implement it, the decision is 100% the team’s to make.

- Project – This idea is complex, might take months, potentially cross departmental, the team can only influence the outcome.

You must only have one ‘Project size’ idea on the table at any one time or it will feel like wading through Christmas Pud.

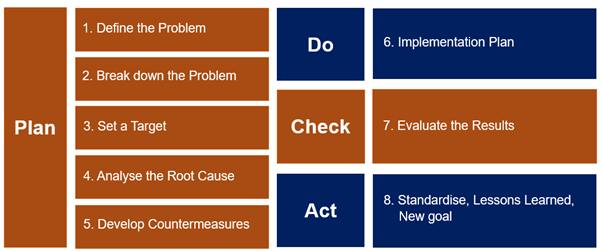

The 4 steps of PDCA – Plan Do Check Act

This 4 step cycle involves creating a plan, implementing it, reviewing the results, and adjusting before restarting the cycle. It is a foundational tool in quality management and is used to systematically identify inefficiencies and implement improvements.

The 5 Lean Principles

Identify Value: What are the parts of your process that your customer values. Developing these generates growth and satisfaction, ignoring these will lead to disfunction.

Map the Value Stream: Visualise the flow of material or information required to delivery our service. Making this tangible supports consistency, understanding, and improvement.

Create Flow: In Lean terminology they call this ‘lowering the water’. Ensure you can see what’s blocking you and holding you back, and remove it to create flow.

Establish Pull: Prevent bottle necks in your processes and reduce nonresponse requests by ensuring the recipient has the knowledge and capacity to support, create that ‘available to help’ signal.

Seek Perfection: In this current rapidly changing economic, political, legislative, and sociological environment we need to be constantly evolving and improving to stay ahead.

The 6 categorises of Measurable Benefit

We have our list of 6 measurable benefits that we use for the projects we are working on.

7 The most common favourite number

The most attended (favourite) training course we run is Effective Time Management with 53 delegates and average evaluation feedback score of 95%. This course as devised was an enabler to our core CI work to ensure everyone had time to make those small daily improvements that have such an impact over time.

The 8 wastes

In CI we live to remove waste from our processes both at work and home. There are 8 recognised categories of waste with a vaguely golfing mnemonic to remember them by.

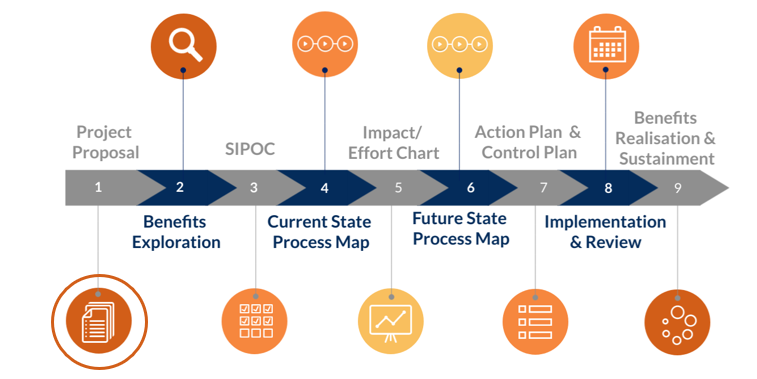

The 9 stages in a Lean Process Redesign Project

10 minutes to plan your day every morning in the DSU

Graeme – By far my favourite CI tool is the Daily Stand-Up. In just 10 minutes each day you support individuals, support the group, head of challenges, surface issues, provide updates, make improvements, maintain engagement, promote inclusion, and if you’re lucky…………you’ll get a top Netflix recommendation that’ll keep you busy for the next couple of nights.

It takes little effort, little education, little change, but makes a huge impact in your effectiveness as a well-functioning team

11 blogs so far this year (not counting this one)

We have covered many topics this year with our blogs starting in January with New Year, New You where Susan G discussed small, incremental changes are more sustainable and effective than big ambitious goals. We reflected on our daily stand ups evolving over time in two separate blogs. We also looked at technology, discovered we are harbouring a technophobe but have others in the team using AI and all the power platform tools. We asked you to ask yourself “is it possible?” and we discovered Susan A still doesn’t like spreadsheets.

12 Years of continuous improvement at Strathclyde

We have been making improvements to processes, offering training sessions on many different topics, measuring benefits and spreading the word about TIM WOODS. We have had 12 years of daily stand ups which started as Communication Cells standing round a board and developed into stand ups where we sit down and use Power BI, but still do the same task.

We look forward to making processes more effective across the university, measuring the benefits, increasing revenue and reducing costs, governing projects and programmes, and continuously improving as we meet the challenges on 2026 head on.

A very Merry Christmas and a Happy (continuously improving) New Year to all.