Why did you choose to do a placement as part of your studies?

I think for Product Design, industry experience is a necessity. Working in industry will allow you to see how real products get designed, built and shipped. There are so many lessons learned from a placement and it gives you clear insight into the realities of the industry. When you’re studying, the marking criteria is clear and your grade reflects how you did. When you’re in industry, all that matters is your quality and effectiveness in getting the work done. It’s a great way to learn and gain confidence and I think it should be considered necessary for anyone wanting to become a Designer.

What happened as part of your placement, what were your roles?

Last summer I was a Product Design Intern at Glasgow-based startup Trtl (pronounced ‘turtle’).

I’d highly recommend getting a placement at a startup or small company because your roles and responsibilities are far and wide. By the end of the placement, I was doing significant work across the Design and Marketing departments, so my roles weren’t limited to the job description. It included everything from being a Project Lead, designing my own products that are going into manufacturing, to hiring and interviewing outside agencies, and also getting to work on the company’s summer marketing campaign, which saw me doing a lot of really fun work on multiple filmsets around the UK and France. Trtl is a pretty young company but there are already three DMEM graduates working at the company. I was lucky enough to have been hired after the placement on a part-time basis, so now I split my time between working there and attending classes.

This was my second placement, which definitely makes it easier because I was more confident than I would’ve been. That said, with each new venture there are new lessons to be learned and Trtl has been full of them.

What have you gained from doing a placement?

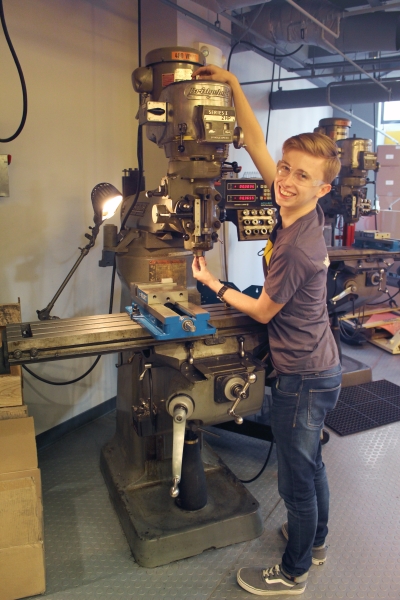

Personally, I got pretty good at logistical skills like picking up the phone to talk to suppliers and arrange meetings. People are quick to send emails and I definitely saved days of emailing back-and-forth just by calling people. It was noticed in the company too and the CEO ended up encouraging more people to do it. Another big learning point was just being ‘comfortable with the uncomfortable’. There were countless situations where I was tasked to get something done and usually under a tight deadline. In these circumstances there is no room for feeling like you can’t do it or are not capable. Building an emotional strength to these situations is key to performing well and I believe Designers really have to work hard in order to be able to take criticism without getting emotionally involved. I will carry the ‘soft skills’ I have built doing my placement with me into the future. Like with any placement, there are also ‘hard skills’ I practiced too, learning the new cloud-based CAD package OnShape, learning how to sew and just getting a bit more confident making models by hand.