Cold spray (CS) is a solid-state powder deposition method that is fundamentally distinct from fusion-based additive manufacturing (AM) techniques such as laser powder bed fusion and laser-directed energy deposition as well as thermal spray processes like high velocity oxy-fuel and plasma spray.

As the process operates below the melting point of the feedstock, CS can preserve the original microstructure of the powder, enabling near-bulk material properties in the final deposit.

Key advantages of CS include:

- No heat-affected zone

- Reduced oxidation and compressive residual stresses

- Lower energy requirements and improved sustainability

- Improved productivity and shorter lead times

- Strong alignment with circular economy and Industry 4.0 principles

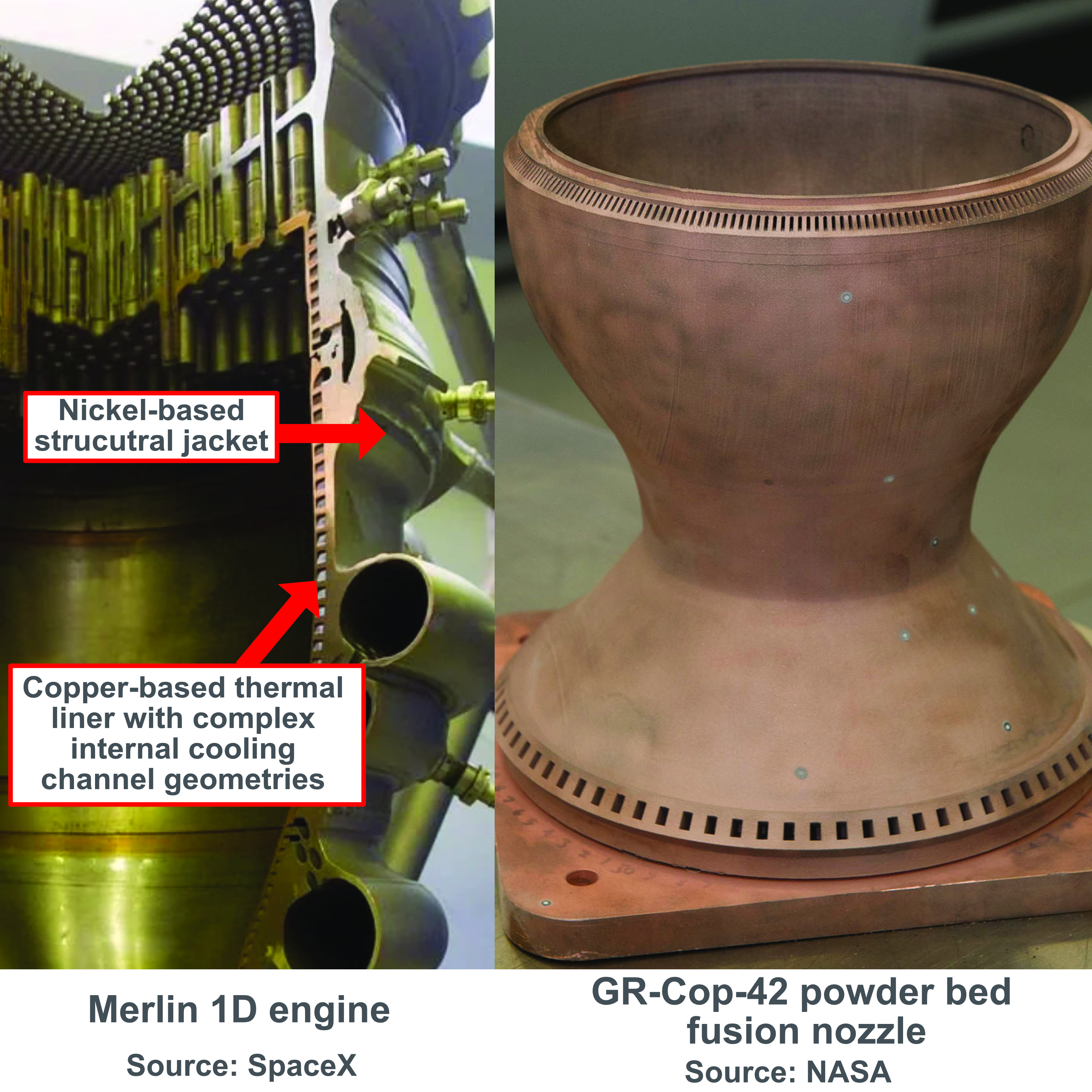

Today, a particular challenge facing the aerospace and energy industries is the AM of components capable of withstanding high mechanical and high heat flux loads. In rocket development, engine combustion chambers have traditionally been the most challenging, and consequently most expensive component to produce. These components feature a nickel-based structural jacket, which withstands the extreme combustion pressures, and a copper-based thermal liner which improves thermal management. The liner, which features complex internal cooling channels, is a well-known and notorious example of a manufacturing challenge which necessitates unique solutions.

To address these challenges this investigation explored the use of CS to deposit GrCop-42, a Cu-Cr-Nb alloy developed by NASA, onto INCONEL® Alloy 718 substrates. GrCop-42 is known for its high thermal conductivity, oxidation resistance, and mechanical strength at elevated temperatures. However, laser-based AM techniques have struggled with its high reflectivity and susceptibility to microstructural degradation in heat-affected zones.

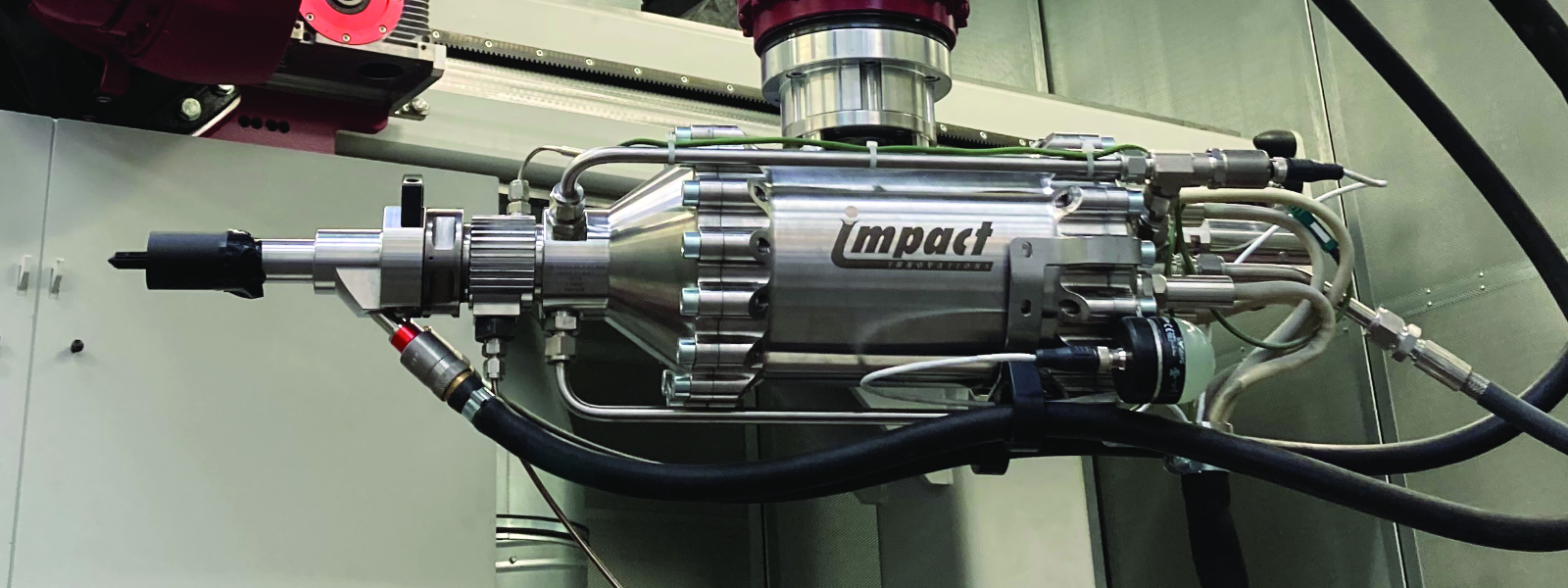

CS offers a promising route to overcome these challenges and enable the manufacture of future aerospace combustion chambers. In this study, GrCop-42 was deposited onto alloy 718 substrates to evaluate the feasibility of CS for this application.

This research represents a step forward in enabling the manufacture of regeneratively-cooled combustion chambers via solid-state AM. As part of this study, the AMRL assessed key properties of the CS deposits, including:

- Microstructure (density, inclusions)

- Chemistry (composition, phase)

- Mechanical properties (hardness, adhesion pull-off strength, cohesion strength)

- Thermophysical properties (co-efficient of thermal expansion, thermal conductivity, thermal stability)

This work contributed not only to CS process development but also to the fundamental understanding of CS in multi-material systems for extreme environments.