Electroplated hard chrome (EHC) has been used extensively across various industries for its exceptional corrosion resistance and durability. However, the production process generates hexavalent chromium, which is an extremely toxic and carcinogenic substance.

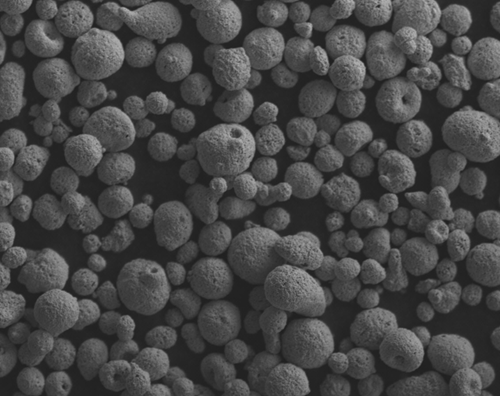

Cold spray technology has emerged as a REACH-compliant alternative to EHC, offering performance that exceeds industrial requirements while remaining environmentally sustainable. Cold spray is a solid-state coating technique in which powder particles are accelerated in a heated gas stream and deposited as thick coatings onto a substrate, with the aim of enhancing mechanical strength, durability, and wear resistance.

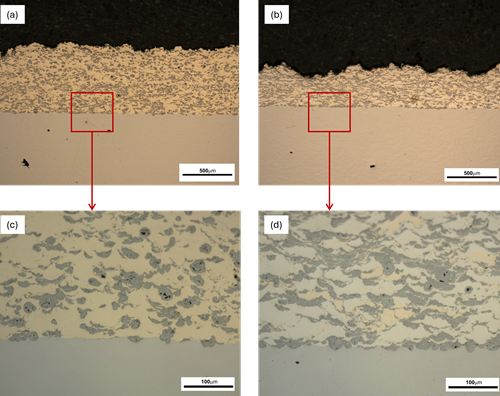

This project investigates two WC–CoCr metal matrix composite (MMC) coatings: one in a nickel matrix and one in Inconel 718 and includes analysis on: morphology, granulometry, microstructure, composition

Standard metallographic preparation and pre-test profilometry were performed, followed by pin-on-disc wear resistance testing. Post-test surface analysis was conducted to identify the dominant wear mechanisms and to perform wear-scar profilometry. The results determine which matrix produces a coating with superior properties and establishes links between powder characteristics, microstructure, and resultant coating performance. As the spraying parameters were identical for both procedures, any observed differences were directly attributed to the matrix material rather than process variations.

_1600x600.png)