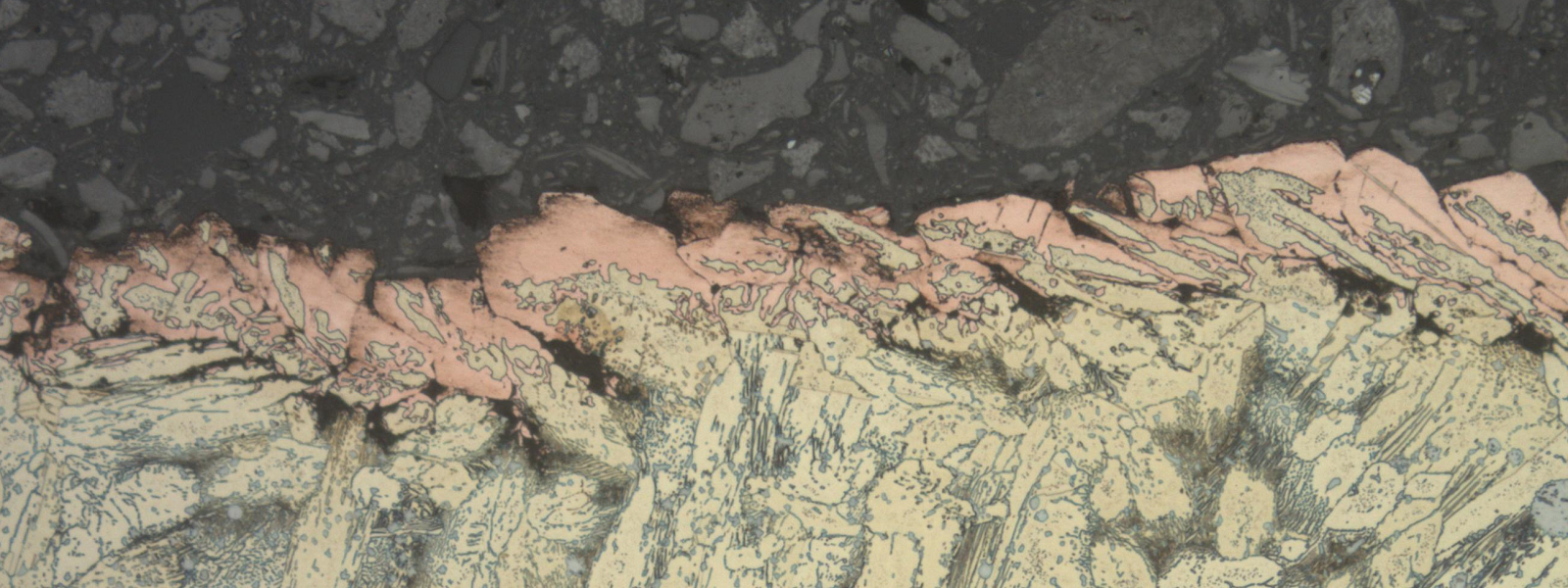

Our expert (Mr James Kelly) has 30+ years’ experience in metallographic preparation and microscopy, with excellent skills in etching a variety of metals and knowledge for interpretation of microstructures.

Advanced Materials Research LaboratoryMetallographic techniques

Abrasive cutter & precision cutter

- Various types and sizes of abrasive wheels to carefully section any specimen

- With a 250mm diameter cutting disc (for the abrasive cutter) and a 150mm disc (for the precision cutter)

- Option to open the side for continuous long materials

- Recirculated coolant to reduce overheating of specimens.

Cold and hot mounting

- Automatic hot mounting presses

- Mould sizes of 30mm and 40mm diameter

- Hydraulic operation with automatic water cooling (for hot mounting)

- Several pressure modes

- Correct encapsulation of material is ensured for grinding/polishing.

Grinders/polishers

- With manual or automatic options

- A selection of rotational speeds and applied loads provide flexibility to suit individual materials

- Selection of different SiC papers and polishing pads for a broad range of material preparation

- Etching solutions for all materials.