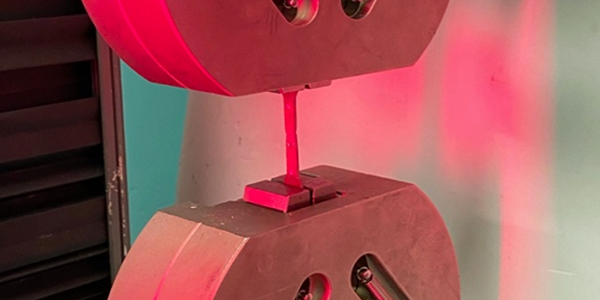

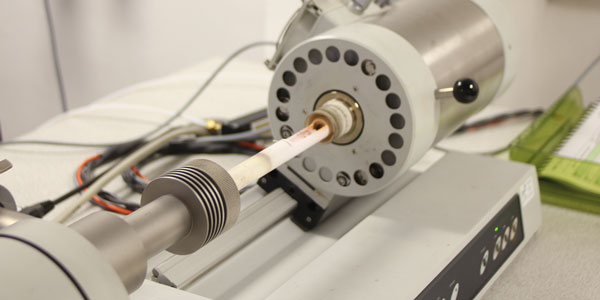

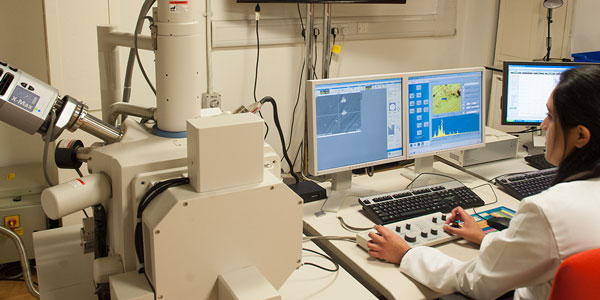

At the AMRL, we can carry out analysis and tests in compliance with internationally recognised standards, such as BS, ISO, ASTM, DIN, etc. We also work with our clients to deliver bespoke testing solutions and the possibility of reproducing operational conditions traditionally not easily accessible. Some examples include:

- Mechanical properties at sub-ambient temperatures and up to 1000°C

- Thermal properties at sub-ambient temperatures and up to 1600°C

- X-ray diffraction at elevated temperatures

- Non-destructive topographical and morphological investigations and elemental analyses of small parts (i.e. no need of materialographic preparation).