Advanced Composites GroupInterface characterisation

Wide ranging applicability

Composite interface is one of the key factors in controlling overall performance in fibre reinforced composites and the Advanced Composites Group set its focus on this area from the very beginning. Over the years we have developed robust micromechanical techniques to probe stress transfer capability in virtually any fibre reinforced polymer composite. These techniques are sensitive to the modification of fibre surface or/and polymer matrix and have been successfully applied to a wide range of fibre-matrix combinations including:

- glass fibre-polypropylene

- glass fibre-epoxy

- glass fibre-nylon

- carbon fibre-polypropylene

- carbon fibre-epoxy

- natural fibre (e.g. hemp, flax, sisal, coir, and palm)-polypropylene

- natural fibre-polylatic acid

- PET fibre-polypropylene

The parameters that have been studied using these techniques to investigate their influence on interfacial properties include:

- glass silane/sizing

- glass composition

- glass heat-treatment

- polymer coupling agent (e.g. MaPP)

- polymer molar mass

- polymer degradation

- composite processing conditions

- carbon fibre oxidation/sizing

- nanoparticle surface treatment

At the frontiers of interface research

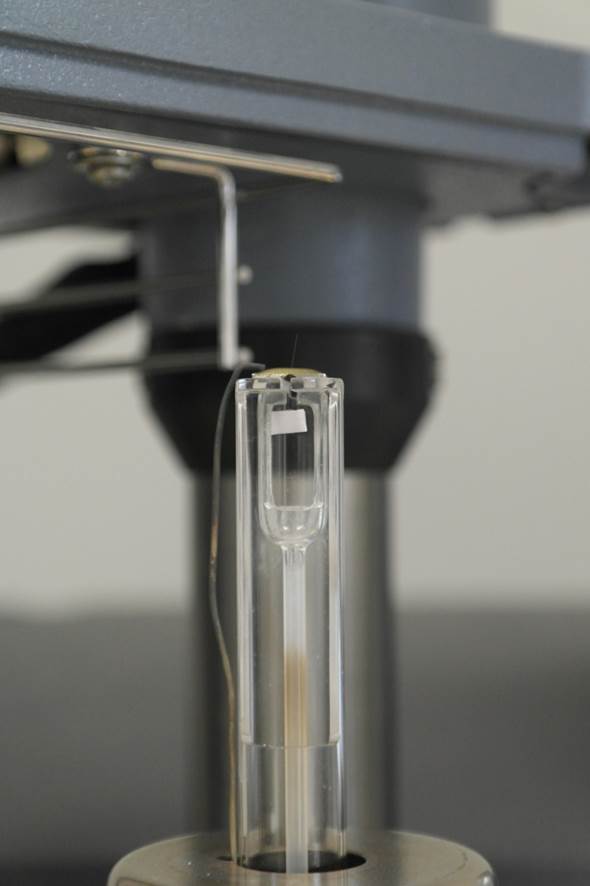

More recent developments in composite interface have been made possible by our novel ability to characterise interfacial properties within the furnace chambers of both Thermo-Mechanical Analyser and Dynamic Mechanical Analyser machines. These new capabilities enable us to investigate the effect of environmental conditions on the composite interface using well-controlled temperature, humidity and atmosphere.

To further extend the capability in the research of composite interface and explore the complexity in fibre-matrix interaction, we are determined to continue developing our expertise in this area by:

- developing automated testing methods for composite interface

- developing in-situ sensing ability during the measurement

- combining computational simulation with experimental process

- extracting information on the interfacial properties through massive composites

Discover our publications and the equipment that supports our research

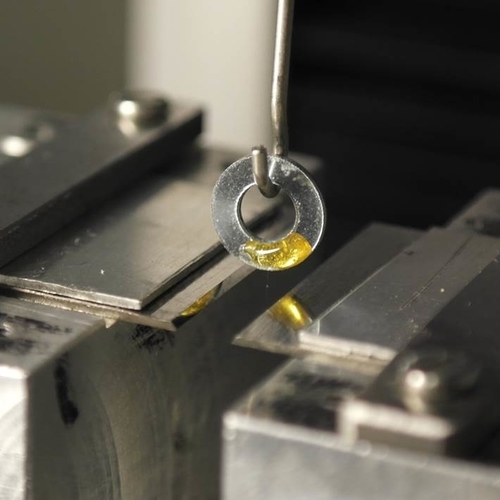

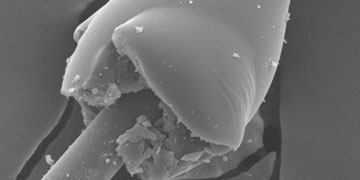

Micromechanical expertise

Our in-house designed equipment allows us to test the interface of a huge variety of fibre-matrix systems