Advanced Composites GroupRecycling, re-processing and re-manufacturing research

At the forefront of glass fibre composite recycling

Our research group is committed to sustainable development of fibre reinforced composites and is at the frontier of the research for developing closed-loop recycling for glass fibre composites. We recently reached the end of a £1m collaborative research grant with 7 other UK universities, together tackling material sustainability in the automotive and renewable energy industries. The outcomes of this research were positive, leading to the filing of a patent on the regeneration of strength of recycled glass fibres (ReCoVeR Licensing Flyer ). Following this success, we maintain a strong desire to continue our cutting edge work on glass fibre composite recyclability.

The glass fibre recycling problem

In excess of 5 million tons of glass fibre is manufactured annually, to be used in glass fibre reinforced polymer composites (GRP). A significant volume of this GRP is used by industries such as automotive and wind turbine manufacture, where the relatively good performance to weight ratio (at low cost) is of great benefit. Approximately 70% of glass fibre manufactured is turned into GRP using thermoset-based matrix materials such as epoxies or polyesters. These materials pose a serious problem regarding recyclability.

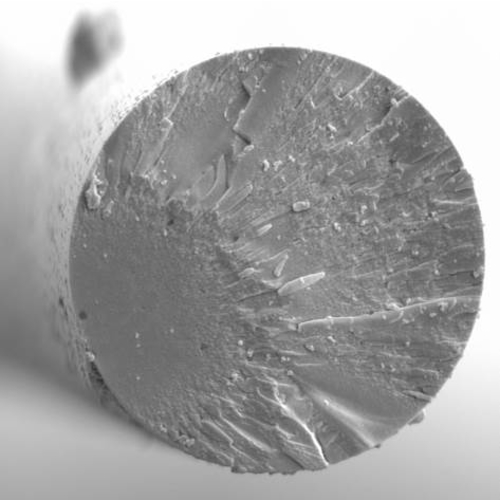

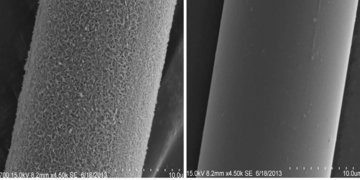

To recycle the fibre reinforcement it is first necessary to seperate it from the matrix. This can be achieved either using chemical solvents or by simply burning off the matrix material. In the latter, temperatures generally in excess of 500 °C are required to degrade thermosets. Unfortunately, exposure to such high temperature causes a significant decrease in the strength of the glass fibres - making them effectively worthless as a reinforcement material. The ReCoVeR treatments pioneered by our team have proven that it is possible to increase the strength of these glass fibres to levels at which they can be an effective reinforcement once again. Furthermore, we have produced strong thermoplastic matrix composites using regenerated fibres. These results have already been published in the literature.

Fibre regeneration

Regeneration of fibre tensile strength was the first roadblock to effective recycling of glass fibre from GRP. Additional research questions such as energy efficient fibre recovery from composites, engineering the interface and processing recycled fibre composites remain continuing goals in our work.

Our ReCoVeR technology represents a significant breakthrough. We have shown that we can recover over 80 % of the original tensile strength of recycled glass fibres. The benefits of a recycled glass fibre product using this technology include the potential to create useful reinforcement material at reduced cost, while simultaneously minimising reliance on landfill to dispose of end-of-life composites.

While our ReCoVeR treatments have been proven effective, we are still actively investigating other possible routes to regenerate fibre strength. Our current focus is the potential of water and water vapour based processes.

Composite recycling and re-processing

In our investigation we thermally recycled composites in air furnaces to obtain glass fibres. However, this is not a very sophisticated method of recycling composites and we are working to pioneer alternatives. These include:

- investigation of possible catalysts to lower required composite degradation temperature

- designing and building a Fluidised Bed Combustion (FBC) process tailored to glass fibre reinforced thermosets

- incorporating degradation enhancing catalysts into the FBC process

Our goal is to incorporate the composite recycling and fibre property regeneration technologies that we develop into a process with a greater level of automation.

In addition to producing useful recycled fibre for second generation composites we are active in researching suitable methods of processing this material. At this time we have been successful in manufacturing simple glass mat thermoplastics by compression moulding.Discover our publications and the equipment that supports our research

Fibre characterisation

Our facilities allow us to characterise mechanical, physical and chemical properties of any fibre reinforcement material