Range of AnalysesMechanical testing

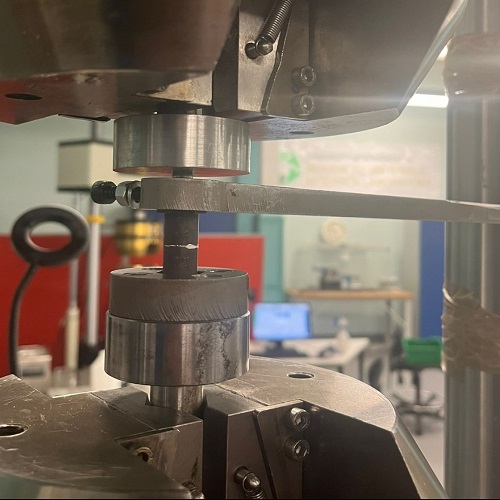

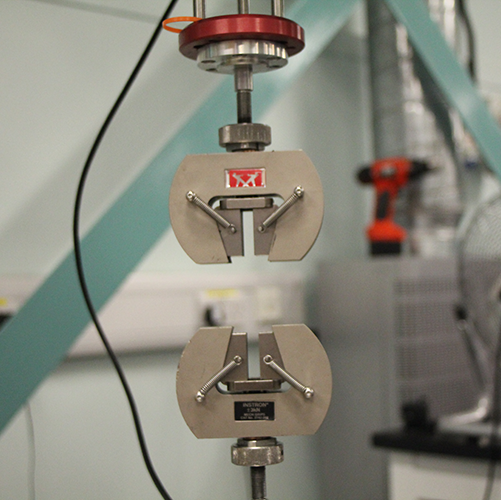

Instron testing suite

- Two 8800 servo-hydraulic systems, dynamic loading capacity of ±250kN

- Electropuls E3000, dynamic loading capacity of ±3kN

- Electromechanical 5969, loading capacity up to 50kN

- Measured properties include tension, compression, axial fatigue, 3- or 4-point bending, shear, creep, galling and fracture toughness (SENT or SENB)

- Testing between -150°C and 1000°C

- Video extensometer for contactless measurements

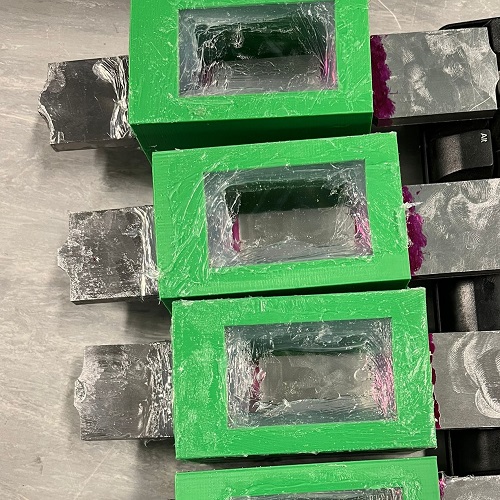

- Fatigue can be carried out also in bespoke environment (e.g. saline solution).

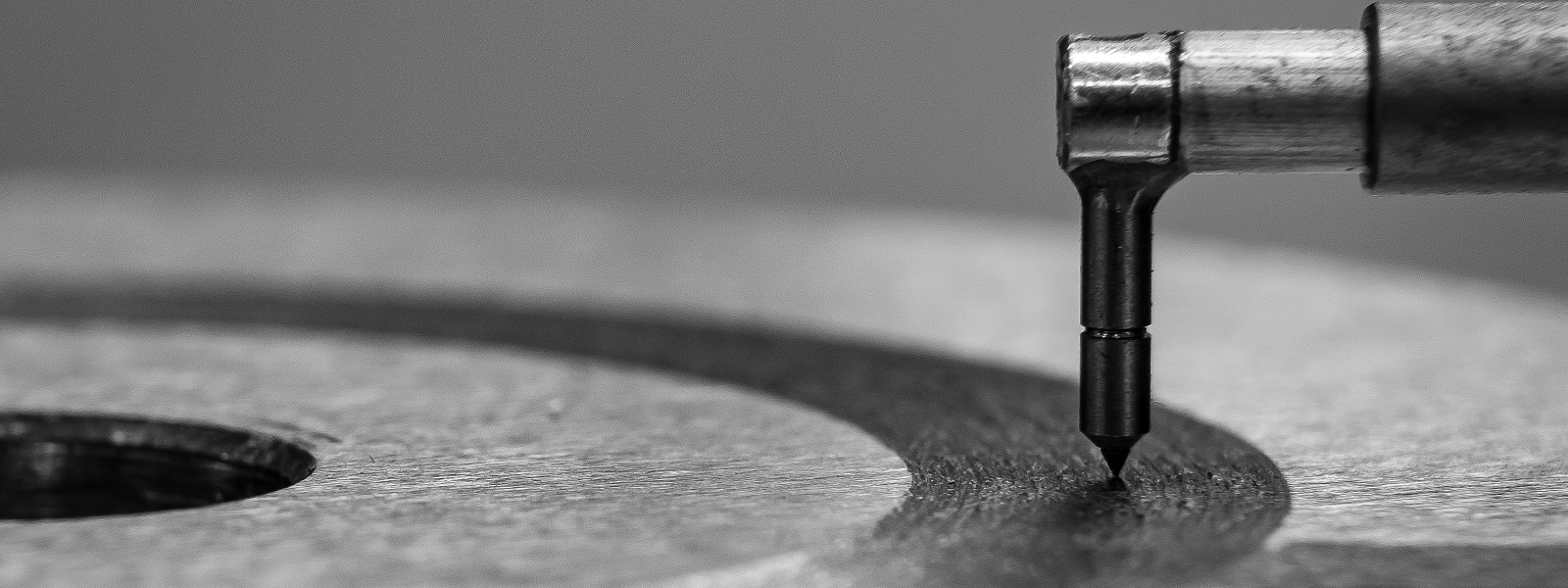

Hardness measurements

- The Qness 60A+ measures hardness with three supported test methods: Vickers, Knoop and Brinell hardness

- Automatic feature for hardness mapping

- Load capability between 0.25g-60kg

- Many applications such as tooth flank testing, identical sample tests and microscopy and weld sample testing and analysis.

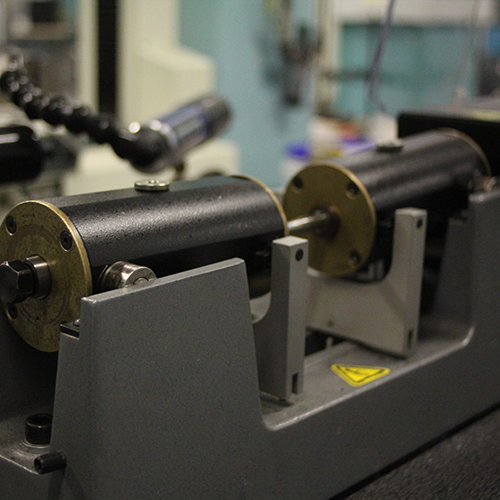

Rotary bending fatigue

- Three R.R. Moore rigs for rotary bending fatigue

- Number of cycles to failure up to 100 million

- Frequency up to 100Hz

- Furnaces available for applications up to 1000°C

- Tests can be carried out in bespoke environments (e.g. saline solution).

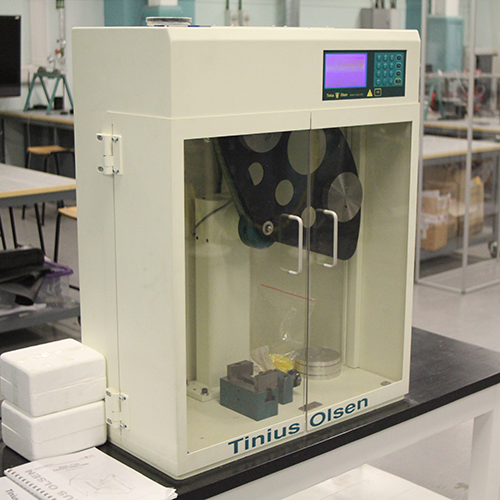

Impact testing

- Tinius Olsen IT503 bench system with either Charpy or Izod configuration and 25J capacity

- Losenhausenwerk system with over 290J capacity

- Both systems fully comply with the specifications outlined in ASTM E23, BS EN ISO 148-3, BS EN ISO 148-2 and ISO 442

- Testing can be completed at sub-ambient and elevated temperatures.

Instron mechanical testing instrument

Test samples in saline solution prepared for testing