In my last blog in the series we covered the third S, Shine, and how we applied this principle in our office area. In this post, I want to focus on how we deployed the fourth S, Standardise.

In my last blog in the series we covered the third S, Shine, and how we applied this principle in our office area. In this post, I want to focus on how we deployed the fourth S, Standardise.

“Where there is no standard there can be no improvement” This is a rough quote from the famous Toyota manager Taichii Ohno.

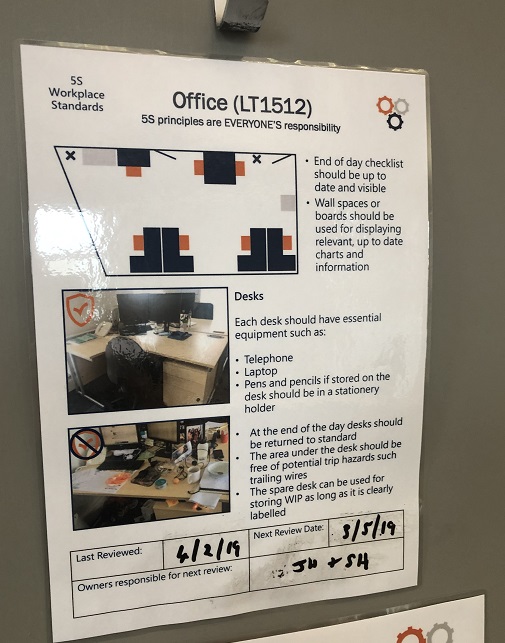

Using the fourth S, Standardise we set about developing a consistently organised workplace. We wanted to create an instinctive approach to how we organise the workplace so that it could not be broken. As a team we agreed, then documented, then displayed the standard we expected of ourselves and of others in each area of the office.

We used the zones that we had created during the sort stage and then took “after” photographs, which formed the basis of the standards we created. Now everybody understands what we collectively have agreed a good workspace looks like so there is a shared understanding about what our current standards are. The pictures make the standards easier to process. The standard we set ourselves promote good behaviours and are a true catalyst in helping us to continually improve.

In my final post in this series, I will be covering how we are sustaining the improvements we have made, and not reverting to old bad habits.