Work with us and unlock access to our technical capabilities. These consist of our cutting-edge equipment, our talented people and their areas of expertise.

Tapping into our capabilities allows you to satisfy your day-to-day operational needs, while safely exploring new opportunities for growth.

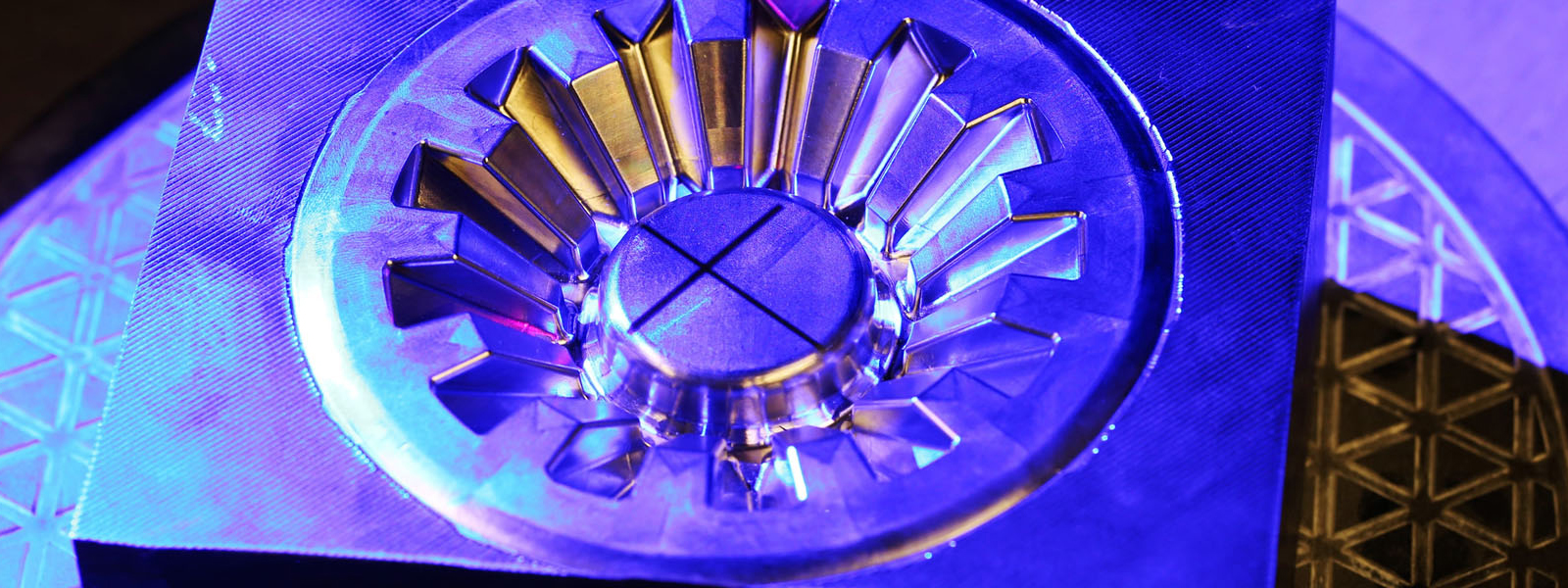

Some of our key technical capabilities:

- State of the art laboratory for residual stress evaluation and strain mapping

- Expertise in superplastic forming, cold forming and hydroforming

- Two MTI rotary friction welding machines, the biggest of their kind in any UK research centre

- Specialists in forming R&D