Along with 17 other partner organisations, the AFRC is involved in a three-year project coordinated by the National Physical Laboratory (NPL) and funded by the European Association of National Metrology Institutes (EURAMET) to look at enhancing process efficiency through improved temperature measurement (EMPRESS).

Most industrial processes need to be maintained at a specific temperature to maximise efficiency; and accurate control of temperature ensures process efficiency. By improving temperature measurement techniques for selected applications, this project aims to enhance the efficiency of high value manufacturing processes in terms of reduced wastage, improved yield, more consistent processing, increased intervals between sensor checks and maintenance, increased reliability, improved energy efficiency and reduced greenhouse gas emissions. Funded by EURAMET’s European Metrology Programme for Innovation and Research (EMPIR), the project is characterised by trials of the developments in-process at end users’ facilities, to solve documented manufacturing problems in high value manufacturing environments and to introduce in-situ traceability to the International Temperature Scale of 1990 (ITS-90).

Duration: May 2015 - April 2018

The specific objectives are to:

- Develop novel low drift temperature sensors for enhanced production and temperature to above 2000 °C: by objective optimisation of the Pt-Rh thermocouple with regards to stability at high temperature; development of carbon thermocouples for use at temperatures from 1500 °C to above 2000 °C; development of a contact thermometer based on sapphire tube and blackbody arrangement for use up to 1800 °C; demonstration of the devices in industrial process environments.

- Develop non-drift contact sensors optimised for heat treatment applications to around 1350 °C: by development of a self-validating thermocouple within a 7 mm ceramic sheath, indistinguishable from current thermocouples used in heat treatment environments; development of novel ultra-stable mineral insulated, metal sheathed flexible Type K/N thermocouples; demonstration of the devices in industrial process environments.

- Develop traceable surface temperature measurement methods to enhance materials/chemical processing to around 500 °C: by development of a contact thermometer for surface temperature measurement based on fluorescence thermometry; development of a contact thermometer for surface temperature measurement based on compensation of heat flow; demonstration of the devices in industrial process environments.

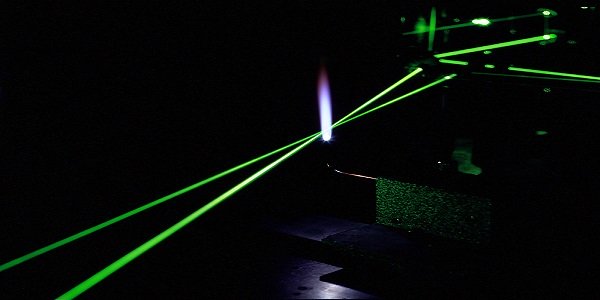

- Develop an in-situ combustion standard of known temperature for the validation of flame temperatures: by development of a portable standard flame; characterisation of the flame (temporal and spatial uniformity, traceable temperature assignment); establishment of a portable flame as a practical resource for establishing ITS-90 traceability in the user community.

Partners

The project brings together 18 partners from the metrology community, high-value manufacturing industry, sensor manufacturing sector and academia.

Community

There is a stakeholder community associated with the EMPRESS project comprising organisations involved in high-value manufacturing who are interested in the project outputs. Members of the community receive regular updates on the project and are invited to workshops to discuss the project. Community members may also have opportunities to trial some of the in-process developments.

If you are interested in joining the stakeholder community please get in touch.

EMPRESS presence on ResearchGate

ResearchGate is mainly used by researchers and scientists to share technical papers and knowledge, discuss new ideas and find new collaborators. EMPRESS project profile on ResearchGate has been created and various relevant publications from the different collaborators have been linked to this profile. Through ResearchGate, technical developments of the EMPRESS project can be disseminated to the scientific community in order to establish connections with potential users/new stakeholders.

Contact

Project coordinator: Dr Jonathan Pearce, National Physical Laboratory, UK