MSc Autonomous Robotic Intelligent Systems

ApplyKey facts

- Start date: September

- Accreditation: Institution of Engineering & Technology

- Study mode and duration: 12 months full-time

Industry Engagement: Competitive internships available

Study with us

This MSc will equip students with the applied, industry-relevant expertise to capitalise upon career opportunities in technology innovation. You will:

- develop advanced knowledge of autonomous systems and machine learning, with a strong emphasis on real-world applications in robotics, sensor networks, and digital manufacturing

- build specialist skills in emerging intelligent technologies, including self-sustaining devices designed for the Internet of Things (IoT), Ubiquitous Computing, and Industry 4.0 environments

- gain hands-on experience guided by industry experts, offering practical insights into the challenges and innovations shaping today’s technology landscape

- foster a comprehensive understanding of system-level design, big data analytics, and cutting-edge developments in artificial intelligence (AI)

The Place of Useful Learning

UK University of the Year

Daily Mail University of the Year Awards 2026

Scottish University of the Year

The Sunday Times' Good University Guide 2026

Why this course?

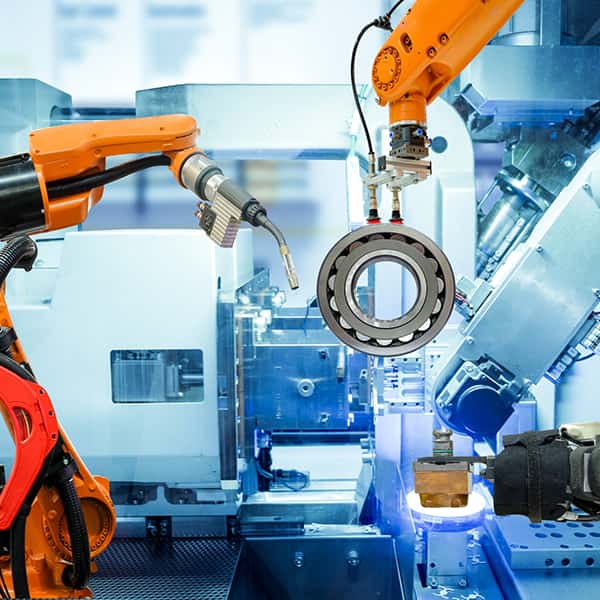

Autonomous systems, artificial intelligence (AI), and modern robotics are transforming industries and redefining how we live and work. Recognised as foundational technologies for the future, their influence is already being felt across a wide range of sectors—from manufacturing, energy, and defence to healthcare, infrastructure, agriculture, and the food and drink industry. As these technologies continue to evolve, so too does the demand for skilled professionals who can harness their potential to solve complex, real-world problems.

This MSc is designed to equip you with the applied, industry-relevant expertise needed to thrive in this dynamic and fast-growing field. Whether you're aiming to launch a career in robotics, smart manufacturing or intelligent systems design, this course provides the technical foundation and practical experience to help you succeed in the multi-billion-dollar global market for robotics and smart machines.

Delivered jointly by the Departments of Electronic & Electrical Engineering, and Design, Manufacturing & Engineering Management, the course offers a truly interdisciplinary learning experience. You’ll benefit from the combined strengths of both departments—gaining insights from leading academics in autonomous and intelligent control, digital manufacturing, and systems design engineering.

Through a blend of theoretical study and hands-on learning, you’ll develop a deep understanding of how intelligent systems are designed, built, and deployed. You’ll also engage with real-world challenges and industry case studies, ensuring that your learning is grounded in the practical realities of today’s technology landscape.

By the end of the course, you’ll be well-prepared to take your first steps into a high-impact career - whether in research, development, or innovation - at the forefront of the intelligent systems revolution.

"This MSc focuses on innovative approaches to heavy engineering, manufacturing and smart machine optimisation. Our partnerships with KUKA Robotics and PEAK NDT, leading suppliers of industrial robots and measurement systems, ensure our students have access to the latest hardware and equipment, helping to solve real-world industrial and societal challenges."

Professor Charles MacLeod

Course Director

What you’ll study

You’ll study a selection of taught compulsory and optional modules exploring all major aspects of autonomous control, intelligent systems and machine learning, with particular focus on robotics, manufacturing and big analytics. These modules are designed to develop advanced knowledge in these topics, enhanced with the leadership, project management and professional engineering skills sought after by employers.

Teaching semesters:

- Autumn semester – September to December

- Spring semester – January to May

Check key dates for your MSc and the University academic session.

MSc Project

Students who pass all required taught modules will progress to the MSc Project, undertaken between May and August, and culminating with the Poster Presentation Day, where they will have the opportunity to showcase their research. MSc Projects involve an in-depth investigation on a topic chosen by the student within the field of electronic or electrical engineering. Projects may be:

- research-based, aligned with current departmental research themes

- industry-based, conducted as an unpaid internship with one of the department’s partner companies

While all projects are designed to address real-world engineering challenges, competitive internships offer additional benefits, including:

- site visits

- access to technical data & facilities

- mentorship from an industry professional

This course structure ensures that students graduate with not only academic knowledge but also practical experience and industry insight.

Poster Presentation Day

In the video below, MSc students talk about their studies and projects at the department's Poster Presentation Day:

Intelligent Sensing & Reasoning through Machine Learning (10 credits)

This module provides the background and skills required to develop autonomous systems based on Machine Learning and Artificial Intelligence. Students will learn the theoretical as well as practical foundations of Data Science (Machine Learning, Deep Learning) for a design and engineering context. Laboratory exercises augment the taught classes to deepen the learning experience. The appreciation of responsible data collection and model training and the responsible design of sustainable solutions are themes that run throughout all lectures.

Neural Networks & Deep Learning (10 credits)

This module provides the background and skills required to develop artificial intelligent systems based on Neural Networks and Deep Learning. Students will learn how to apply the main methods used for machine learning and neural networks and to solve engineering challenges. They will also gain an understanding and appreciation of the breadth of applications, issues and limitations of these tools, and their role in supporting automated decision-making.

Manufacturing Automation (10 credits)

This module aims to introduce students to the concepts and basic technology of manufacturing automation and to be able to select suitable applications and specify the type of automation to be used in specific cases.

The module covers: Automation in manufacturing industry, why and where; Industrial robots, automation and typical applications; Open and closed loop control; Problems in robot design and control; Types of motion control; Control system functions; Advantages and disadvantages of electric and fluid power systems; Types of electric motors and their control techniques, simple actuators for hydraulic and pneumatic systems; Methods of programming robots; Relative economics of human labour, reprogrammable and hard automation and Safety considerations for industrial robots and other automated systems.

At the end of this module students will be able to:

- Demonstrate knowledge and understanding of why manufacturing automation is used

- Describe the conditions under which manual and/or automated production methods would be applied

- Analyse the configuration and technical specifications of an automation system suitable for a specified task

- Synthesise a manufacturing task suited to a specified automated system

- Analyse and understand the technological elements of drive and control, and machine vision, systems

- Critically appreciate the kinematic and dynamic problems associated with the control of automated systems

- Understand the implications of applying automation in human terms

- Demonstrate knowledge of safety factors that must be considered when installing automation

Assessment and feedback is in the form of one coursework submission showing technical analysis of an aspect of automation and critical thinking on the design of systems (40%), an exam (50%) and in-class participation (10%).

Mechatronic Systems Design Techniques (10 credits)

The module will cover the following topics:

- mechatronic system design process: Product/system design specifications (PDS), concept generation and selection, mechatronic system design and flow chart diagrams.

- sensing and actuation: Sensing theory, sensor selection, drive design, motor control.

- control systems: Understand and apply control theory in a mechatronic system design.

- hardware design: Processor architecture, embedded computing platforms, interface, I/Os.

- software design: Software design basics, algorithm and code design, programming tools, and software engineering principles.

- prototyping and evaluation: develop skills in selecting methods for prototyping using appropriate tools and means, including rapid prototyping and computer modelling.

Robotics & Control Systems (20 credits)

This module aims to provide an introduction and overview to the various core aspects of robotics which include design, control, sensing and localisation. It provides a solid base of understanding through theory and examples. Intuition is encouraged through numerous hands-on examples.

The module covers: Robotic systems including background, classification of robots based on design construction, control systems; Performance characteristics of typical robots; forward kinematics of robots including Denavit-Hartenberg (D_H) algorithm and inverse kinematics; Robotic control including principles of system modelling, Matlab implementation, time and frequency domain analysis and control system analysis; Bayesian robot localisation including linearization and Kalman Filtering; Robotic computer vision in particular when applied to mapping and localisation.

At the end of this module students will be able to:

- describe types of robotic systems, their dynamic and mechanical architecture and associated sensor technology

- describe appropriate path-planning techniques taking into account ways to perform collision avoidance and speed up optimal path evaluation

- understand standard camera models and common approaches to image registration

- use computer-based tools to evaluate designs, measure, record and report experimental and numerical data relevant to robotic and other computer control systems

- formulate models from given relevant information and design control systems to drive these models to specified positions and within required accuracy, speed and other performance-related parameters

Assessment and feedback is in the form of a final exam (60%) and coursework which will be a mixture of multiple choice quizzes and laboratory work (40%).

Sensor Technologies (20 credits)

This module will provide you with a broad appreciation of modern sensor technologies and their implementation in industrially relevant applications.

Assignment & Professional Studies (20 credits)

The aim of this class is to provide you with support for your general academic and professional development.

You'll undertake an advanced investigation of an electronic or electrical engineering topic of your choice, to enhance your learning, and develop presentation and communication skills.

You’ll study no more than 20 credits of optional modules. Please note that the below is an indicative list of modules, reflecting the curriculum in the current year. These modules are subject to change, but are likely to include:

Strategic Technology Management (10 credits)

This module aims to provide a series of strategic frameworks for managing high-technology businesses. The main focus is on the acquisition of a set of powerful analytical tools which are critical for the development of a technology strategy as an integral part of business strategy. These tools can provide a guiding framework for deciding which technologies to invest in, how to structure those investments and how to anticipate and respond to the behaviour of competitors, suppliers, and customers. The course should be of particular interest to those interested in managing a business for which technology is likely to play a major role, and to those interested in consulting or venture capital.

At the end of this module students will be able to:

- Demonstrate a comprehensive understanding of the role and importance of technology in business strategy formulation process

- Develop the ability to critically assess concepts, tools and techniques of managing technology for both stable and turbulent business environments

- Evaluate complexity and develop appropriate technology strategy models for specific cases

Grades will be determined by class participation assessed through four two-page papers on case studies, which may be written in groups of 4 people (40%), and an individual final technology strategy report based on an in-depth exploration of technology strategy in an assigned industry (60%). There is no final exam.

Product Modelling & Visualisation (10 credits)

This module aims to enable students to understand the concepts of virtual product modelling and techniques used to visualise products before they are fully designed and manufactured.

The module covers: an introduction to basic modelling, visualisation and evaluation techniques creating models, parts and assemblies; The representations that underpin modern CAED systems (wireframe, surface, CSG and BRep), basic computer graphics (homogeneous transformations), data exchange, information integration, product data management, economics of CAD/CAM systems (cost breakdown, potential benefits, improving cost/benefit ratio), basic systems selection and justification and organisational impact and system management.

At the end of this module students will be able to:

- demonstrate the ability to use a commercially available CAD system by creating 3-D product models and appropriate visualisations for evaluation

- demonstrate knowledge and understanding of product modelling and visualisation by demonstrating an ability to provide 2D/3D part and assembly drawings, and a variety of sectioned/dimensioned views of part/assembly models

- demonstrate knowledge and understanding of product evaluation techniques by identifying and describing suitable product evaluation techniques such as FEA and utilise for evaluation

- describe and discuss the functionality and benefits that CAED systems can bring to product development by identifying and justifying a CAED solution for an industrial problem

Assessment and feedback is in the form of coursework (100%).

Design Methods (10 credits)

This module aims to enable students to select and apply appropriate design methods as a part of the design process.

The selection and use of design methods within the context of modern design practices and the new product development process will be explored. Emphasis will be placed on recently developed product independent design methods and their application within industrial environments. Specific topics include the design process management frameworks, user understanding methods, product specification methods, creative methods, design for production and cost methods, design for safety and reliability methods and design for the environment.

At the end of this module students will be able to:

- select and apply appropriate design methods for a design project to solve product design oriented problems by understanding specific design methods and recognising their strengths and weaknesses

- integrate appropriate design methods into a design process to ensure fitness of purpose of all aspects of the problem/context by demonstrating how manufacture, costing, environmental, disposal and customer needs may be addressed in the design process through design methods

- analyse literature sources to identify design methods suitable for a particular situation by undertaking a critical literature review to identify current developments in design methods in research and practice and synthesise the results of the literature review into a report

Assessment and feedback will be in the form of an exam (60%), a report (35%) and a presentation (5%).

Digital Manufacturing Concepts (10 credits)

This module aims to provide students with knowledge and understanding of the key concepts for Digital Manufacturing, current practices, tools and processes, and possible future development routes.

The module covers the current state of digital manufacturing, including tools and processes and identification of challenges and areas requiring further development in terms of research and technology innovation, product and service development, supplier management, production, routes to market, delivery, in service, maintenance, repair, remanufacture and reuse, and business plan development and management aspects. Digital manufacturing developments are also considered including the exploration of life-phases, challenges and technologies, Industry 4.0, Smart Products, Internet of Things, Cyber Physical Systems, value chains and value creation through life.

At the end of this module students will be able to:

- Demonstrate an understanding of the key concepts for digital manufacturing and stages of development of the manufacture of a chosen product

- Discuss different digital manufacturing approaches

- Provide an overview of the tools, processes and practices currently employed in digital manufacturing

- Identify challenges and opportunities for improvement

- Understanding of current worldwide initiatives for the future development of digital manufacturing, and exploration of how proposals for future development given would affect the current processes

Assessment and feedback is in the form of coursework (100%) including a group presentation and a report.

Systems Thinking & Modelling (10 credits)

This module aims to introduce students to the theories and principles of Systems Thinking. The module also introduces the methods, tools and techniques for modelling, analysing, improving and designing systems in a variety of organisations including industrial, commercial and public sector.

The module covers: Systems theory, concepts and approaches; Hard and soft systems analysis and systems dynamics; Systems and organisational performance – including leadership in a systems environment and ‘design’ in a systems environment and Practical application of Systems Thinking.

At the end of this module students will be able to:

- show clearer understanding and knowledge of hard and soft approaches and how they can be used to deal with complexity and system behaviour in a business context

- develop understanding of fundamental cybernetic principles that form the foundations of Checkland’s Soft System Methodology and Beer’s Viable System Model

- develop knowledge and skills in systems analysis and business process modelling

- critically evaluate the most appropriate methodology to model, analyse and design engineering/business systems across a range of organisations

- demonstrate an understanding of how to model a business system and to develop a solution to solve a business system problem

- develop an awareness of the importance of system approaches in management interventions

Assessment and feedback is in the form of a group presentation and one coursework in the form of a reflective diary.

Embedded Systems Design (20 credits)

This class provides hands-on experience in translating Digital Signal Processing concepts into real-time embedded systems applications.

Through a combination of lectures, up-to-date technical discussions and hardware programming, you'll learn to design and implement real-time embedded systems through familiarisation with Digital Signal Processors and FPGAs.

Design Management (10 credits)

The module will teach the following:

- background and design for competitiveness and sustainability

- integrated Product Development, and different approaches and aspects to design development including concurrent engineering, team engineering, product management, design management, distributed design, and decision support

- the design activity, methods and process models including the role of the market, specification, conceptual and detailed design

- basic team and management structures (organisation)

- key issues related to design complexities (e.g. relating to the people, processes, resources, product, key considerations, knowledge and information, decision making) and the key aspects of design co-ordination

- design performance and innovation

Design for Industry 4 & Smart Products (10 credits)

This module aims to provide students with knowledge and understanding of the key concepts for the Design for Industry 4 and Smart Products, current practices, tools and processes, and possible future development routes.

The module covers the current and latest state-of-the-art in Design for Industry 4 and Smart Products, including the identification of challenges and areas requiring further development in terms of research and technology innovation, product and service development, supplier management, production, routes to market, delivery, in service, maintenance, repair, remanufacture and reuse, and business plan development and management aspects. It also explores the latest initiatives worldwide that tie with Design for Industry 4 and Smart products (Industrial Internet of Things (IIoT), Cyber Physical Systems, Cloud Manufacturing, Big Data analytics and Edge Analytics, Additive Manufacturing for Smart Products, IIoT Security aspects) and Through-Life Engineering and Through-Life Engineering Services (TES) concepts.

At the end of this module students will be able to:

- Formulate an overview of the tools, processes and best practice currently employed in Design for Industry 4 and Smart Products

- Understand initiatives currently undertaken worldwide for the future development of Design for Industry 4 and Smart Products, and assess how proposals for future development given would affect the current processes.

Assessment and feedback is in the form of classwork (100%) including a group presentation and a report.

Micro & Nano Manufacturing (10 credits)

This module aims for the student to acquire: (1) knowledge of the fundamentals of micro- and nano-products and of the manufacturing of such products (MEMS, micro-fluidic devices, micro-medical devices, micro-motors, microrobots, MOEMS, etc.), size-effects, material/interface behaviour at the micro-/nano-scale, challenges to manufacturing at low length-scales, etc.; (2) knowledge of micro-/nano-materials processing methods, techniques, industrially-viable processes, etc. and (3) experience and skills in the design/selection of micro- /nano-manufacturing processes, tools and equipment for real-world products.

It covers material behaviour, challenges, processes (subtractive, additive, deformation, replication, joining, hybrid processes including mechanical, thermal, chemical, electrochemical, electrical methods) and tools, machines and manufacturing systems.

At the end of this module students will be able to:

- Explain key techniques used in the processes for the manufacture of micro-products

- Correctly select technologies for specified products and materials

- Demonstrate calculations of forming/cutting forces involved and analysis of stresses/temperatures involved in tools/machine-frames/workpiece as appropriate

- Deliver a machine design (either for micro-machining or micro-forming) with detailed analysis and module designs, including a cost analysis on the machine designed.

Assessment and feedback is in the form of coursework (40%) and a project (60%), including a group project presentation and project report and individual assignment.

Advanced Forming Technology Systems (10 credits)

This module aims to provide students with knowledge and understanding of the underlying principles of the metal forming theory and practice as applied to modern metal forming machines, tools and processes.

The module covers concepts and definitions including stress, yield condition, strain, flow laws, plastic work, evolution equations, meso and micro-scale approaches; limiting phenomena (shape accuracy, plastic flow localisation, fracture, tool strength, friction, microstructure); metal forming machines and tooling; bulk metal forming; sheet metal forming and incremental forming.

At the end of this module students will be able to:

- Describe stress/strain relationship for metals undergoing plastic deformation

- Explain the mechanism of plastic deformation at the meso and micro scale

- Explain the effect of different factors on the net-shape forming capability

- Discuss metal forming problems resulting from material and tool interaction

- Explain limitations of the metal forming technology due to a tool/machine system

- Discuss major elements and challenges for a forging system

- Explain the idea and give examples of incremental metal forming operations

Assessment and feedback is in the form of an exam (80%) and coursework (20%)

Advanced Materials & Production Technology (10 credits)

This module aims to provide students with an introduction to the fundamentals of advanced materials, characterisation and advanced surface engineering. The module also covers advanced machining processes and technologies and the principles and practices of rapid prototyping and manufacturing.

The module covers: Severe plastic deformation, materials properties and characterisation; Advances in Machining including the machining of hard materials, high-speed machining, precision grinding technology; ultra precision diamond turning and grinding technology; Principles and practice of Layered Manufacturing; Advanced Surface Engineering including physical-chemical functionalisation, electro-deposition, CVD, PVD, tools/mould treatment, nano- and multi-layered coating.

At the end of this module students will be able to:

- Describe processes of materials selection, characterisation, ultra-precision machining, rapid prototyping and advanced surface engineering

- Demonstrate know-how on key processing parameters and show numerical and analytical skills relating to the materials and process selections and parameter setting

- Identify key process parameters/variables in relation to process control and product quality

- Specify machines or manufacturing systems for the manufacture/creation of specified products/models or to propose design solutions for a manufacturing machine/system to address the manufacturing requirements identified

Assessment and feedback is in the form of four pieces of coursework (25% each).

Advanced Microcontroller Applications (20 credits)

Provide advanced competence in the use of industry standard microcontrollers programmed in low and high level languages in real time applications.

Image & Video Processing (20 credits)

Control Principles (20 credits)

This module aims to introduce the basic concepts, mathematical tools and design methods of classical control theory. It also introduces students to advanced control methods and provides a basic understanding of a time-domain approach to control analysis and the design of industrial processes.

The module covers: First and second order systems, delay process, simple saturation models; Simulation tools such as GUI, SIMULINK, MATLAB; Control system performance, transient and steady-state figures of merit, time domain step response, reference tracking and disturbance rejection in time domain; Simple control principles; State space representation of linear systems; Continuous time and discrete-time system fundamentals: eigen-values & eigen-vectors, stability, controllability & observability, canonical forms for systems; State-space control methods: pole placement state feedback control with/without observer design and linear quadratic optimal control.

At the end of this module students will be able to:

- model simple systems with transfer function and state space representation, create simulations using MATLAB and Simulink

- analyse linear open loop and closed loop systems both in frequency and time domain

- understand the theoretical and practical implications of feedback control systems, design control systems using simple PID tuning methods

- assess control performance, make analytical calculations and critical evaluation of control performance-related metrics

- apply and understand the advanced control methods, principles and applications in an industrial context

Assessment and feedback is in the form of a coursework and class test in Semester 1 (15%), a project report (15%) and exam (70%) in Semester 2.

Advanced Digital Signal Processing (20 credits)

Develop the necessary skills that will allow you to analyse, design, implement and simulate advanced DSP techniques and algorithms for a variety of communications and general engineering problems.

Knowledge & Information Management for Engineers (10 credits)

This module aims to give students an understanding of the types of knowledge, techniques and systems used in building knowledge-based systems and discussion on the application of these techniques; and, an understanding of the types of different approaches, techniques and systems used in building information-based systems.

The module covers an introduction to knowledge based systems; knowledge representations; reasoning, chaining and searching and an introduction to information systems; information input and retrieval; information modelling process and techniques; information normalisation; visual modelling; information structure and organisation; and integration of information systems.

At the end of this module students will be able to:

- Demonstrate an understanding of Knowledge and Information Management

- Demonstrate an understanding of Knowledge Models and Methods

- Demonstrate an understanding of Knowledge Engineering and Development Processes

- Design, develop, implement and report on an appropriate information system to meet the identified information requirements

Assessment and feedback is in the form of group coursework (50%) and individual coursework (50%), there is no exam

Students who successfully pass all required taught compulsory and optional modules will progress to the MSc Project.

MSc Project (60 credits)

The aim of the research project is to provide you with an opportunity to bring your knowledge and skills together and deploy them in a significant practical investigation, using relevant engineering literature, and where relevant, initial experiments or simulations.

Learning & teaching

The MSc is delivered through a blended learning approach, combining both in-person and online methods to provide a flexible and engaging educational experience. Teaching methods include:

- lectures (in-person & online)

- problem-solving tutorials

- hands-on, project-based laboratory sessions

This approach is designed to equip you with advanced technical expertise, while also developing essential leadership, project management, and professional engineering skills.

Each module typically includes:

- five hours of direct contact time per week

- at least five additional hours of independent study, supported by the University’s virtual learning environment, digital research resources, & library facilities

This structure encourages you to take an active role in your learning and to deepen your understanding through self-directed exploration and research.

Assessment

Each module employs a variety of assessment methods designed to maximise your learning and help you realise your full potential. These methods may include:

- coursework – involving research, design & analysis tasks

- examinations – testing core theoretical knowledge & problem-solving

- lab reports – documenting technical investigations

- presentations – developing the ability to communicate complex ideas clearly & professionally

- group projects – fostering collaboration & innovation skills

- final MSc Project – a substantive piece of independent work demonstrating mastery of a specialist area

Weighting of assessments

Taught modules account for two-thirds (120 credits) of the total assessment, while the MSc Project contributes the remaining one-third (60 credits).

The project is assessed based on the technical quality and contribution of an interim and final report, a poster presentation and demonstrated initiative, independent thinking and project management skills.

This diverse assessment structure ensures that you are not only tested on your academic knowledge, but also on your ability to apply it in real-world and professional contexts.

Professional development & employability

We are committed to helping you build a strong professional network and enhance your employability. In today’s competitive job market, having the right skills, training, and mindset is essential for career success.

To support your development, the MSc offers:

- access to cutting-edge facilities & state-of-the-art laboratories

- guidance from academic experts who are leaders in their fields

- opportunities for industry engagement through internships, guest seminars, careers events & networking sessions

These experiences are designed to help you develop not only technical expertise, but also the professional confidence and connections needed to thrive in the global communications sector.

Facilities

The department teaching spaces alongside a dedicated Masters Project and Study Environment for self-study and group working. You’ll benefit from access to these, as well as internationally leading research centres and state-of-the-art facilities dedicated to topics covered within the MSc. These include the Advanced Forming Research Centre (AFRC), the National Manufacturing Institute Scotland (NMIS) and the Digital Process Manufacturing Centre.

Industrial partnerships with the likes of KUKA Robotics, PEAK NDT, MathWorks, Spirit Aerosystems (Europe) Ltd, and Rolls-Royce ensure first-hand experience of the latest technologies and systems in use, and how these help to address real-world challenges.

Access to these facilities is designed to support you with your project, offering opportunities to investigate issues such as digital manufacturing, machine intelligence and autonomous control, swarm robotics and systems design.

Entry requirements

| Academic requirements | Normally a first-class or second-class honours degree (or international equivalent) in electronic, electrical, communications or design manufacture engineering, or a science-related subject. |

|---|---|

| English language requirements | If English is not your first language, please visit our English language requirements page for full details of the requirements in place before making your application. |

Pre-Masters preparation course

The Pre-Masters Programme is a preparation course held at the University of Strathclyde International Study Centre, for international students (non-UK/Ireland) who do not meet the academic entry requirements for a Masters degree at University of Strathclyde.

Upon successful completion, you'll be able to progress to this degree course at the University of Strathclyde.

Glasgow is Scotland's biggest & most cosmopolitan city

Our campus is based right in the very heart of Glasgow. We're in the city centre, next to the Merchant City, both of which are great locations for sightseeing, shopping and socialising alongside your studies.

Fees & funding

All fees quoted are for full-time courses and per academic year unless stated otherwise.

Take a look at our scholarships search for funding opportunities.

Fees may be subject to updates to maintain accuracy. Tuition fees will be notified in your offer letter.

All fees are in £ sterling, unless otherwise stated, and may be subject to revision.

Annual revision of fees

Students on programmes of study of more than one year (or studying standalone modules) should be aware that the majority of fees will increase annually.

The University will take a range of factors into account, including, but not limited to, UK inflation, changes in delivery costs and changes in Scottish and/or UK Government funding. Changes in fees will be published on the University website in October each year for the following year of study and any annual increase will be capped at a maximum of 10% per year. This cap will apply to fees from 2026/27 onwards, which will not increase by more than 10% from the previous year for continuing students.

| Scotland | £12,550 |

|---|---|

| England, Wales & Northern Ireland | £12,550 |

| Republic of Ireland |

If you are an Irish citizen and have been ordinary resident in the Republic of Ireland for the three years prior to the relevant date, and will be coming to Scotland for Educational purposes only, you will meet the criteria of England, Wales & Northern Ireland fee status. For more information and advice on tuition fee status, you can visit the UKCISA - International student advice and guidance - Scotland: fee status webpage. Find out more about the University of Strathclyde's fee assessments process. |

| International | £32,800 |

| Additional costs | Course materials & costsAll students should expect to pay around £100 for additional course materials and other associated costs. You are not required to buy any specific software licences as all software used in classes will be available locally or remotely on campus machines. Some hardware (microcontrollers, design boards) may be available for loan purposes subject to a refundable deposit. If you choose to purchase these for project work, they cost approximately £10 to £30. Access to department computer labs out of normal working hours is via key card. This costs £20, but is refundable upon return of the card. You are provided with a printing quota for department lecture and tutorial notes, available for use in work conducted in department computer labs. You can buy top-ups if required through University IT Services. Some printing and report binding will be required as part of your course. This is provided by the department’s dedicated Resource Centre. Costs are likely to be about £10 to £20 per year, but will depend on the exact programme and classes taken. International studentsInternational students may have associated visa and immigration costs. Please see student visa guidance for more information. |

Please note: the fees shown are annual and may be subject to an increase each year. Find out more about fees.

Scholarships available for September 2026

Faculty of Engineering International Scholarship for Masters Study

We are delighted to offer our Faculty of Engineering International Scholarship for Masters Study for applicants to postgraduate taught degrees starting in September 2026. The scholarship award of £6,000 will be deducted from tuition fees.

Dean's International Excellence Awards

We also have a limited number of Dean’s International Excellence Awards for postgraduate taught applicants joining the Faculty of Engineering in September 2026. These scholarships are worth between £9,000 and £12,000 and will be offered to exceptional applicants at postgraduate taught level only.

How can I fund my course?

Scottish postgraduate students

Scottish postgraduate students may be able to apply for support from the Student Awards Agency Scotland (SAAS). The support is in the form of a tuition fee loan and for eligible students, a living cost loan. Find out more about the support and how to apply.

Don’t forget to check our scholarship search for more help with fees and funding.

Students coming from England

Students ordinarily resident in England may be to apply for postgraduate support from Student Finance England. The support is a loan of up to £10,280 which can be used for both tuition fees and living costs. Find out more about the support and how to apply.

Don’t forget to check our scholarship search for more help with fees and funding.

Students coming from Wales

Students ordinarily resident in Wales may be to apply for postgraduate support from Student Finance Wales. The support is a loan of up to £10,280 which can be used for both tuition fees and living costs. Find out more about the support and how to apply.

Don’t forget to check our scholarship search for more help with fees and funding.

Students coming from Northern Ireland

Postgraduate students who are ordinarily resident in Northern Ireland may be able to apply for support from Student Finance Northern Ireland. The support is a tuition fee loan of up to £5,500. Find out more about the support and how to apply.

Don’t forget to check our scholarship search for more help with fees and funding.

International students

We've a large range of scholarships available to help you fund your studies. Check our scholarship search for more help with fees and funding.

Scholarships & funding support

Each year, we offer an extensive range of scholarships for new Home, UK, EU, and international students to help with tuition and living costs. These are offered at university and faculty level, as well as by our industry partners.

Careers

The global robotics and smart machines market is projected to grow significantly over the next decade, driven by advances in AI, automation, and digital transformation. Employers are actively seeking graduates who can bridge the gap between theoretical knowledge and practical application—precisely the kind of expertise this MSc delivers.

Potential career paths include:

- Robotics Engineer – designing and developing intelligent machines for manufacturing, healthcare, logistics, and more

- AI & Machine Learning Specialist – building algorithms and models that power smart systems and data-driven decision-making

- Systems Integration Engineer – ensuring seamless communication between hardware and software in complex automated environments

- Smart Manufacturing Consultant – helping companies adopt Industry 4.0 technologies to improve efficiency and innovation

- IoT Solutions Architect – creating connected systems that gather and analyse data in real time across industries

- R&D Engineer – working at the forefront of innovation in autonomous vehicles, drones, or next-generation robotics

Recent graduates have gone on to technical and professional roles within organisations such as CISCO, AWS, Texas Instruments and Siemens. They have also capitalised upon opportunities within:

- Technology companies & robotics startups

- Multinational manufacturers & engineering consultancies

- Healthcare technology firms & research institutions

- Government agencies

- PhD programmes & academic research roles

What could I earn?*

| Role | Potential earnings |

|---|---|

| Robotics Engineer | Entry level positions in the UK start at round £37,800 per year, rising to an average £46,000. Salaries for more senior roles are about £61,000 |

| Automation Engineer |

As a new graduate, you can expect to start on around £40,000, rising to an average salary of £47,500 per year. This could increase to £62,500 for the most experienced workers |

| IoT Architect |

Typical UK graduate salaries start from £43,000 a year, with average annual salaries reaching £75.000. At senior or management level, this can increase to at least £85,000 depending on the type of company worked for |

| Systems Engineer | Average earnings for a systems engineer in the UK is £40,200 per year, rising to £52,000 for senior roles |

Information is intended only as a guide. Salary detail acquired from Talent.com, June 2025.

The course’s strong academic foundation, combined with hands-on experience in the state-of-the-art Sensor Enabled Automation & Robotics Control Hub lab, significantly enhanced my technical skills. Strathclyde’s focus on research and industry collaboration has given me the confidence and knowledge to excel in my career in automation and robotics.

Automation & Control Engineer, CMAC

Apply

To apply, click on the relevant apply button

As part of the admissions process, you must upload the following supporting documentation. We will be unable to process your application if these are not provided:

- official semester mark sheets/academic transcript showing subjects taken and grades achieved for all qualifications. If you're still studying, please provide your individual semester mark sheets to date

- certified degree certificate for all qualifications. If you're still studying, please provide this after completing your qualification

- evidence of suitable English language proficiency if English is not your first language, or you're not from a “UKVI recognised "Majority English Speaking" country”; check the University’s language requirements

- if you have been out of full-time education for over two years, provide a CV, detailing employment history, organisations worked for, and a brief description of roles and responsibilities demonstrating expertise, skills and suitability for the programme

- a copy of your passport containing your photo and passport number

- a copy of your sponsor letter/scholarship award (if appropriate)

- names, job titles and email addresses of two nominated referees

Start date: Sep 2026

Autonomous Robotic Intelligent Systems