Design, Manufacturing & Engineering ManagementOur facilities

Welcome to DMEM

Home to state-of-the-art facilities and tools to help design, prototype, manufacture and perform research on a broad range of items.

Undergraduate community facilities

Explore our undergraduate student community area, including collaboration working areas, computer suites and social areas, as well as vending machines, lockers and digital display boards.

Postgraduate Taught community facilities

See where our postgraduate taught students can revise, relax and work in groups in their community areas, including collaboration areas, computer suites, digital presentation boards and social areas, as well as a kitchen.

Postgraduate Research community facilities

Check out our Leonardo Suite, a postgraduate research community area, including individual desks, group working areas, white boards, meeting rooms and a shared kitchen.

Digital Design and Manufacture Studio (DDMS)

Our dedicated CAD/CAM digital facility with rapid prototyping equipment.

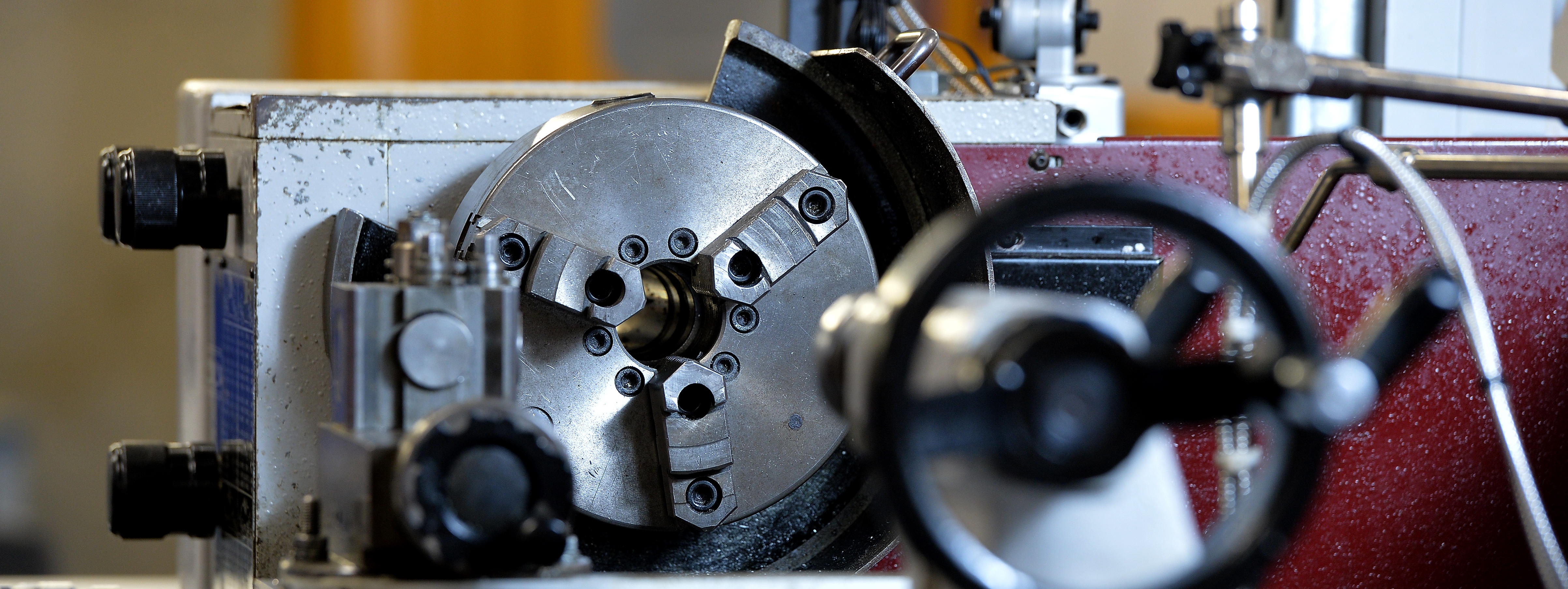

DMEM Workshops

Creative areas providing students with access to materials and equipment to allow their prototyping ideas to become a reality.

Teaching Spaces

The Studio allows for flexible workshop style teaching, showcases, presentations and guest lectures.

Advanced Forming Research Centre (AFRC)

A globally-recognised centre of excellence in innovative manufacturing technologies, R&D, and metal forming and forging research.

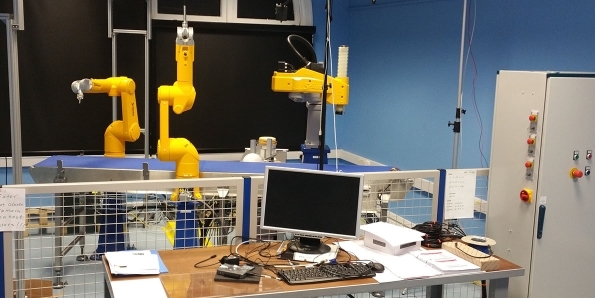

Mechatronics Equipment

Our facilities which advance teaching and research in robotics, programming and smart mechanisms.

Metrology Laboratory

Equipment to advance knowledge in the science of measurement.

DMEM Research Equipment

We have many researchers in our Department furthering their discoveries in creativity, design and innovation, materials, operations, sustainability and technology.

Contact us

Get in touch if you want to find out about using our facilities, expertise and equipment.